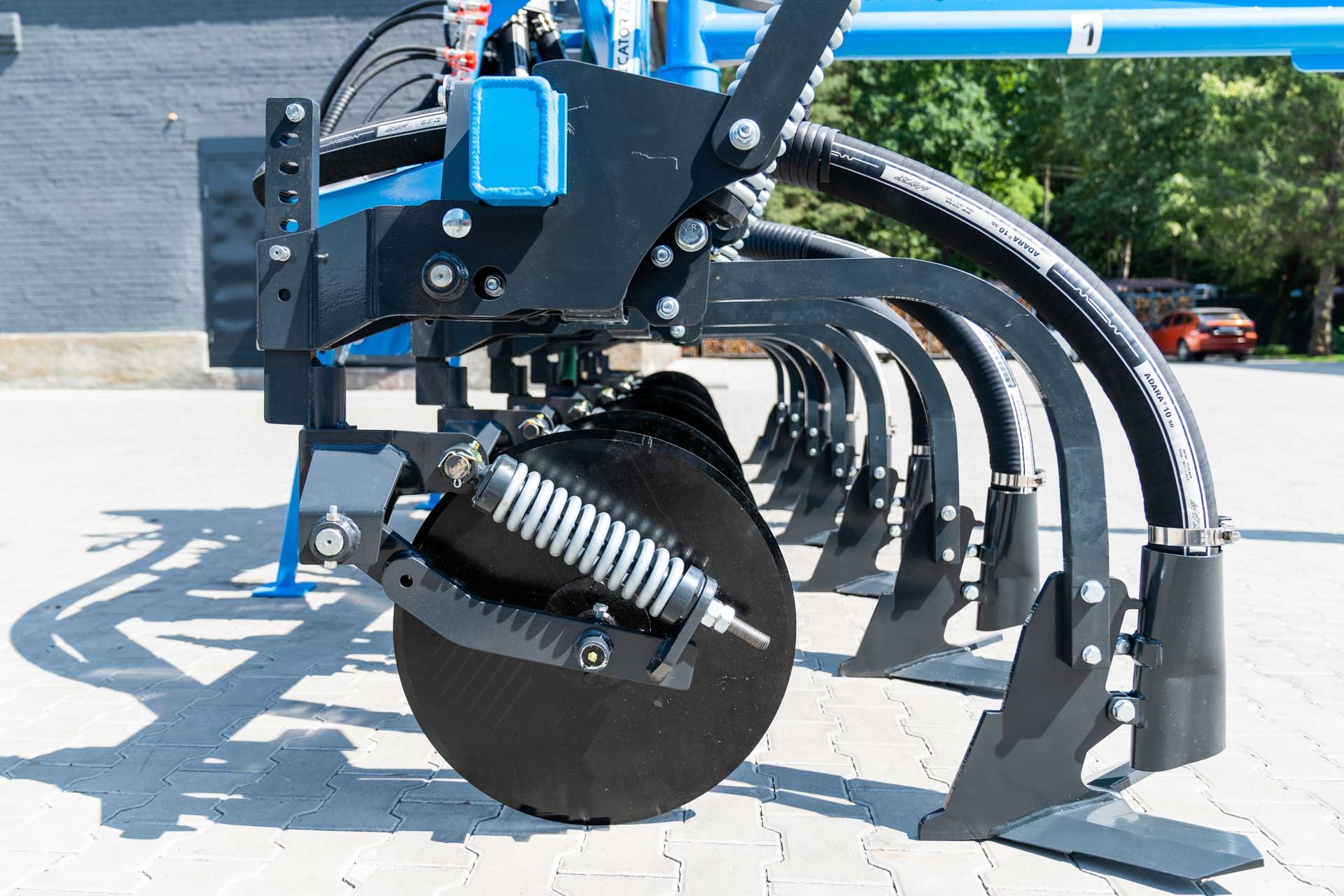

A.TOM 9 DS «SMART FLOW» has 6.55 m operation width and 9 working tools, including Dietrich shank, which allows to incorporate organic fertilizer to a 15 cm depth, that helps to increase fertility by penetrating to a predetermined depth and accumulating organic fertilizers in the root system of plants.

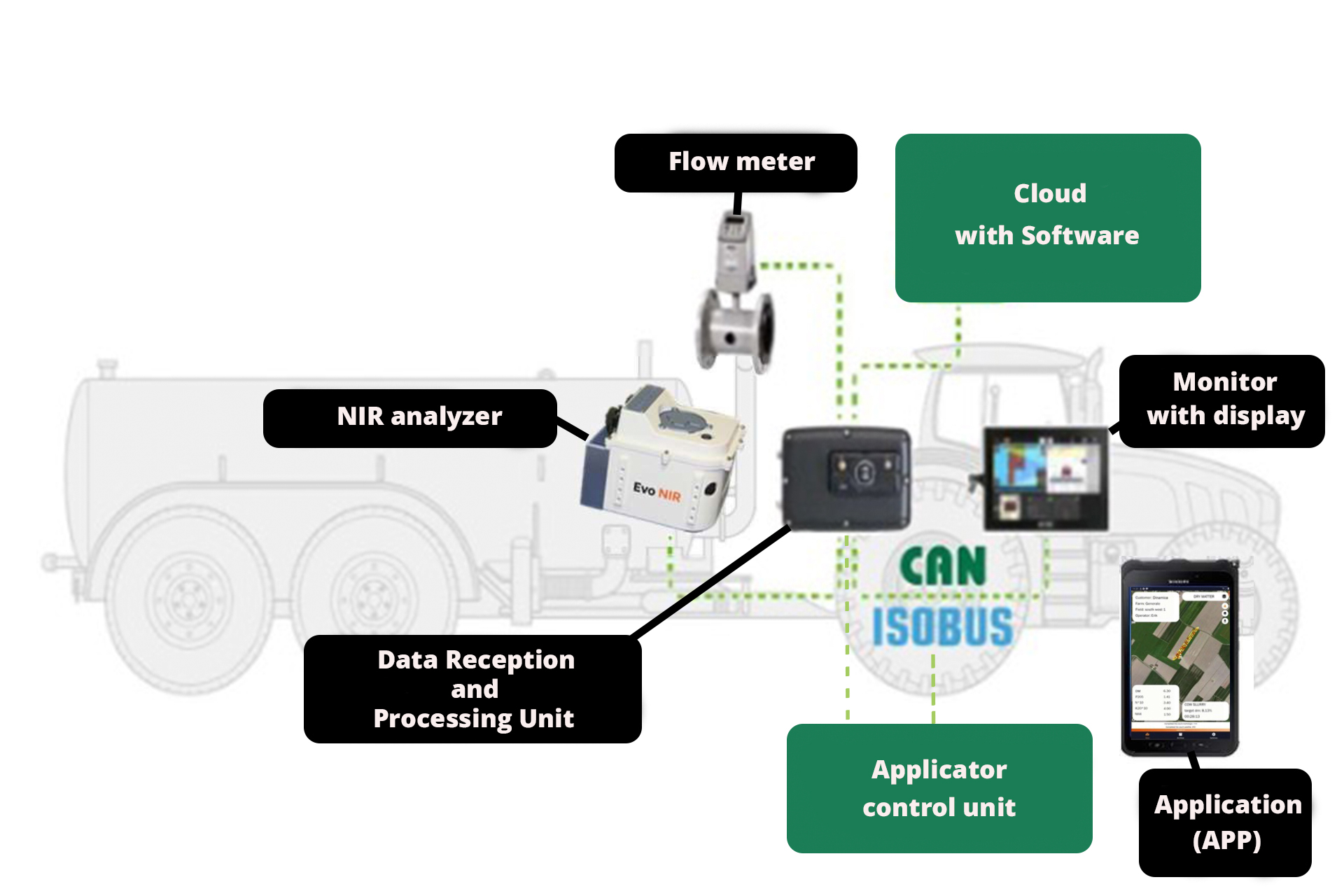

Evo NIR 4.0 ARCHITECTURE

EVONIR 4.0 is the most versatile NIR analyzer that can be used for a variety of applications, such as in manure tanks or hose systems. Thanks to its near-infrared technology combined with artificial intelligence algorithms, it can analyze and determine the exact composition of not only crops, but also cow and pig manure and digestate from biogas plants. Manure is a valuable source of nutrients for soil fertilization and should be used wisely, depending on its NPK and ammonia concentration.

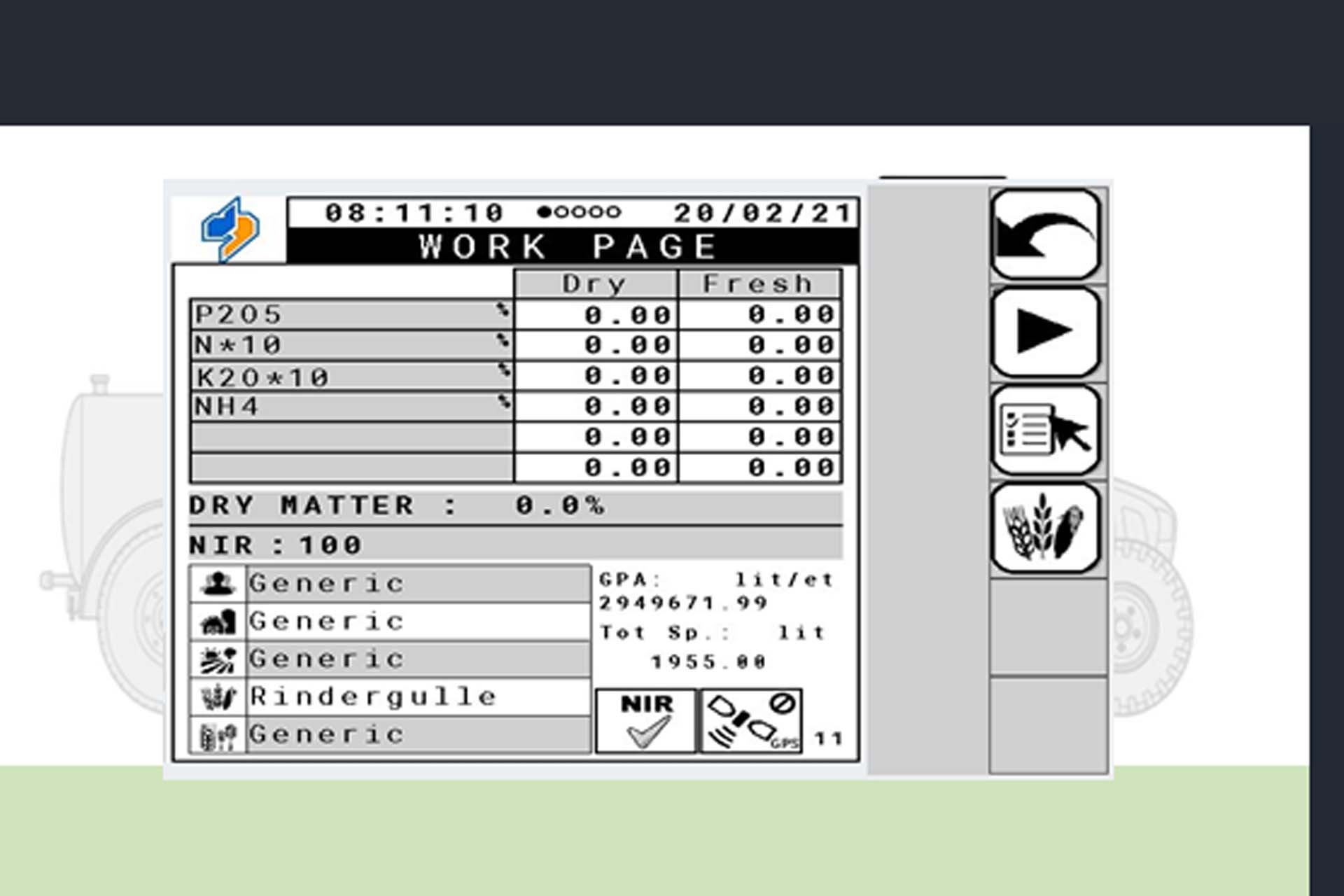

EVONIR 4.0 analyzer can determine the concentration of the following constituents in the slurry:

- Dry matter (DM)

- Total nitrogen (N total)

- Ammonia (NH4)

- Phosphorus (P2 O5 )

- Potassium (K2 O)

Based on Flowmeter data and NIR values ManureXControl ECU can determine optimal tractor speed or adjust the flow acting on slurry tanker pump: VARIABLE RATE. The options (tractor speed/flow adjustment) depends on the slurry tanker model (in case of drag-hose injectors the only option available is the tractor speed).

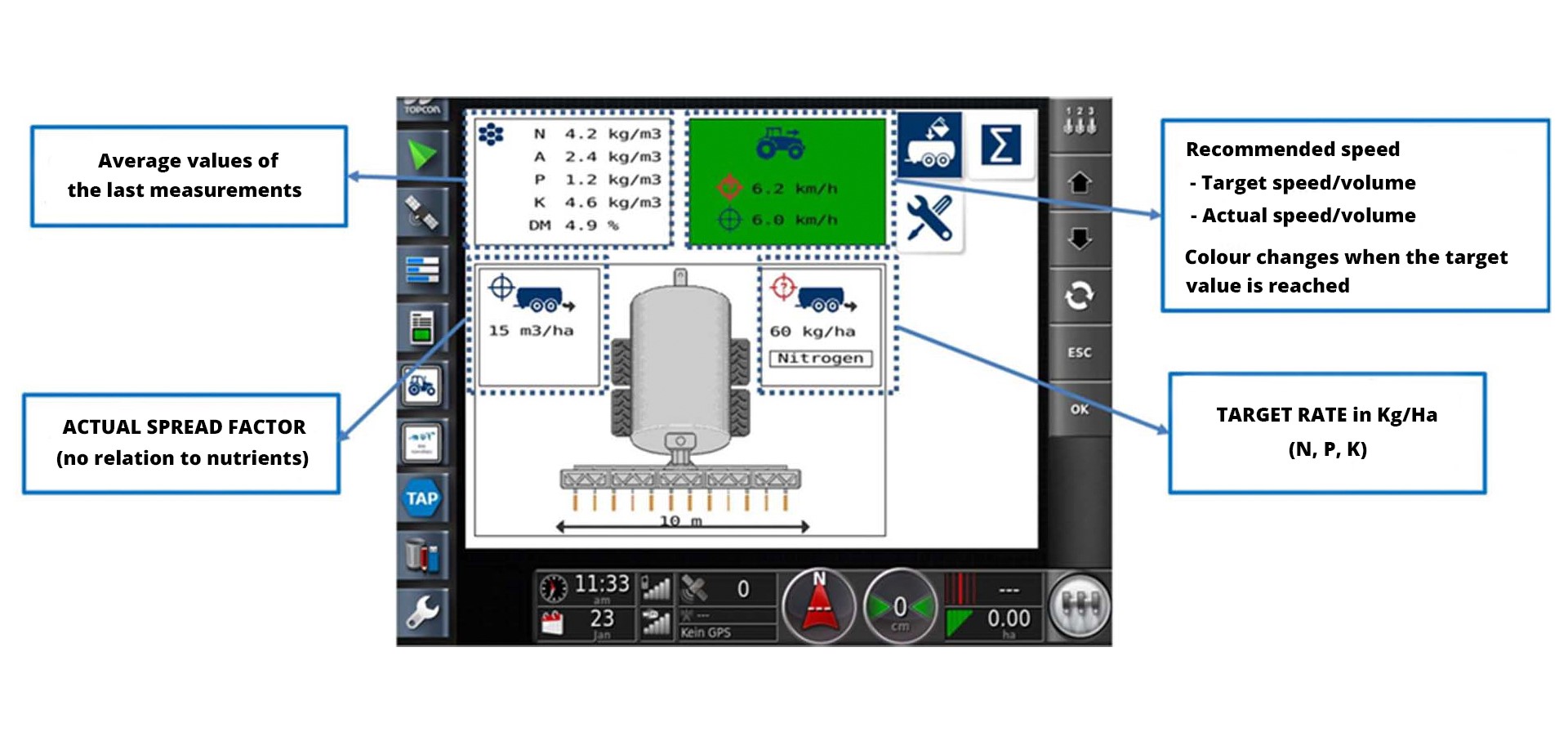

EvoNIR 4.0 + Virtual Terminal + Flow Meter _Variable Rate Solution

EvoNIR 4.0 + Virtual Terminal + Flow meter

Data that can be visualized on a virtual terminal :

- Info general: Customer, farm, field, component (cow slurry, pig slurry, digestate).

- Real time NIR analysis for the following parameters: DM, Ntotal, P205, K2O, NH4.

- GPA: gallons/liter per acre/hectare (real time SPREAD FACTOR). This value it is not linked to the concentration of slurry nutrients.

- TOTAL SP: total number of gallons/liters spreaded since the driver pressed PLAY button to start analyzing.

- Real time mapping of DM if the VT has task controller.

The operating conditions of the manure applicator require sufficient durability and robust design. Applicator body is made of high quality structural steel grade S355 J2 and powder polymer coating as it works in an aggressive environment.

One of the distinctive features of this applicator is folding frame, which provides mobility and convenience during transportation. The applicator's structure has a dual frame that folds and unfolds for easy transportation. The beam cross-section is 150 mm x 100 mm, with a thickness of 8 mm.

Metal stabilizing supports, which are folded and unfolded, are fixed vertically with a lock pin in the unfolded position. They raise the applicator and keep it at a certain height for aggregation with the tractor. After the end of work, they fix the applicator in a stable position.

They are used to maintain the set working depth and to perfectly follow the terrain.

For the convenient loading and unloading, the applicator is equipped with mounting loops.

The applicator has a three-point hitch for tractors of categories 3 and 4.

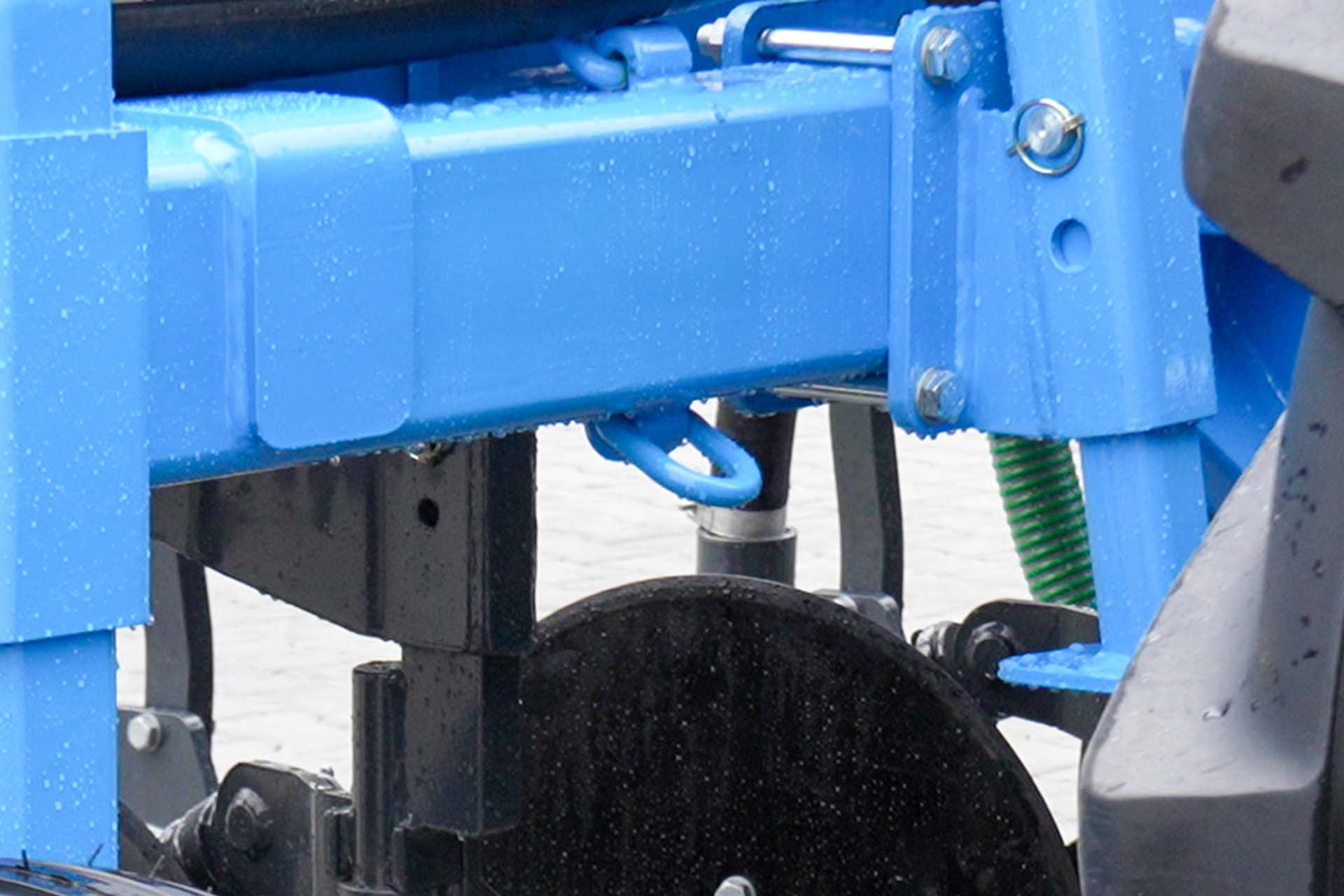

Powerful hydraulic cylinders with a strong rod are used for folding and unfolding the frame wings.

A robust 152 mm reinforced turning pipe, rotates around a vertical axis.

A high-performance electromagnetic flow meter Optiflux 2300 from one of the world's best manufacturers of equipment for applications requiring high measurement accuracy - the German company Krohne. It is used to measure the flow of the material being supplied . The flowmeter is mounted in a rotary pipe and secured with reinforced studs.

To support the weight and stabilize the rotating pipe.

One of the unique elements of the applicator is the articulated hose with a double swivel mechanism. This device protects the hose from damage when the tractor turns and prevents the hose with pressurized liquid from twisting.

Seals and bearings require periodic lubrication at certain intervals, the applicator's design includes conveniently placed grease points. For lubrication, we use SAE universal grease with extreme properties (EP), in particular, Nils Nilex EP 2 grease (Italy).

Guillotine slide valve is hydraulically closed to block the flow of liquid when the tractor is turning at the edges of the fields, which prevents excessive amounts of organic fertilizer from spilling out.

The distribution of manure between the working bodies is carried out through a liquid flow distributor with 7 outlets with a diameter of 75 mm. The distributor is powered by a hydraulic motor.

From the flow distributor, the liquid is delivered to the working tools through distribution hoses with a diameter of 75 mm, designed for a pressure of up to 10 Bar. We use "Adara" pressure distribution hoses from one of the best European hose manufacturers –“BrinkoflexGmbh” (Germany).

Used for receiving, processing and transmitting data.

Drives and controls all functions of the unit.

Analyzes and determines the exact composition of cow and pig manure and digestate from biogas plants.

-cat16.png)