Filter

Filter:

A manure (slurry) applicator – advantages of technology

A manure (slurry) applicator is equipment for applying liquid organic fertilizers, which is used at the final stage of liquid manure utilization from biogas plants using hose systems. According to the type of application, such equipment can be for surface and subsurface applications.

Manure applicator: purpose and features

The choice of applicator type is based on the application period (pre-sowing or post-harvest) and agro-climatic conditions. For example, on a field with alfalfa, you need to apply about 100 m3/ha of organic matter - this is a perennial grass, so the field could not be mechanically processed. And in the case of corn for silage, you can use subsurface equipment and apply 120-160 m3/ha.

The use of subsoil applicators is the most innovative solution and has the lowest cost of 1 cubic meter of applied liquid material. This type of applicator allows applying material into the soil to a depth of 20 cm, which gives a lot of advantages compared to surface application, for example, reduction of air pollutant emissions with an unpleasant odor, which is especially important when the fields are close to the living area. In the sub-soil method, the liquid fraction is distributed inside the soil layer, which minimizes the loss of valuable nutrients. As a rule, the application depth is 5–18 cm. It means that the main micro and macro elements contained in the organic material reach the root zone of plants, in the most effective and quickly accessible form.

The regulation of applied material, based on the type and consistency, is carried out either by changing the productivity of pumping stations or as a result of a change in the speed of the tractor that tow the applicator, with a constant flow rate of the pump-diesel station. The slower the tractor with the applicator moves, the more material is applied per m2 of a field area.

The regulation of the application rate by changing the speed of the unit is the most efficient solution. For calculating the speed of movement with a given application rate, our experts developed a special algorithm that takes into account:

- type of equipment,

- working width, number of working bodies,

- depth of manure application,

- design features of working bodies,

- minimum and maximum speeds.

A table that is based on this algorithm allows to determine the speed of the tractor, when changing the productivity of the transfer pump. It should be emphasized that a change in productivity is possible for several reasons:

- a change in the composition of manure, the percentage of solids in it,

- a change in the length of the hose line,

- height differences, etc.

For increasing the efficiency of sub-soil applicators in the hose system, tractors are equipped with a cartographic GPS positioning system and flow meters. Based on the calculated data, the operator can control the exact amount of application, constantly monitoring the application area on the system monitor display, thereby avoiding the possibility of application insufficient or excessive volume or re-application. Agronomists, in turn, can monitor the work according to received planning maps with the designation of zones and application volumes, which are automatically made by the system. The automatic application map is generated accurately and does not require additional operations.

Application maps will allow memorizing the boundaries, size, and shape of the field. The entered parameters will serve as basic information for determining the volumes of subsequent application.

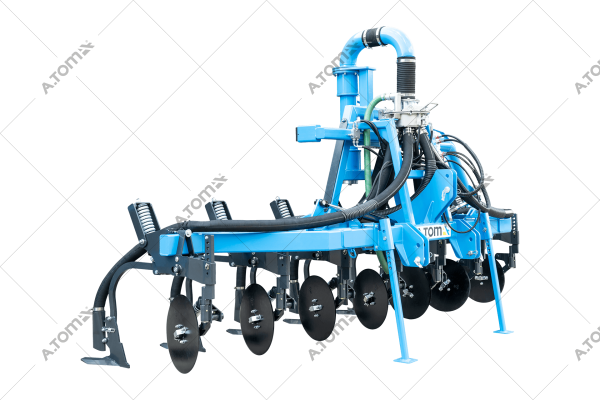

A.TOM Slurry Applicator 7 DS

Our company manufactures and sells A.TOM Slurry Applicator 7 DS for subsoil application of manure. This model has 4.5 m grab width and 7 working bodies, including a Dietrich shank, which allows to apply organic fertilizer to a 15 cm depth, which helps to increase fertility by penetrating to a predetermined depth and accumulating organic fertilizers in the root system of plants. Cutting discs located in front of the shank carry out cutting of the stubble.

Advantages of Dietrich shank:

- compact mechanism;

- spring protection of both leg racks and cutting discs;

- adjustment of the protective springs force;

- cutting disc with 572 mm diameter;

- individual adjustment of the cutting disc depth;

- reinforced rack with a cross-section - 32 mm (transverse dimension) x 51 mm (longitudinal dimension);

- high volume center hoe;

- the increased distance between the blade and the rack of the center hoe (57 cm) eliminates the risk of jamming with corn and sunflower stems.

Among the other distinguishing characteristics of this applicator, should be mentioned lifting wings of the frame, which ensures mobility during transportation and storage.

One of the unique advantages of A.TOM applicator is its hose protection system - a swiveling pipe with a double rotary coupling, this device protects the hose from damage when the tractor turns and prevents the hose from twisting.

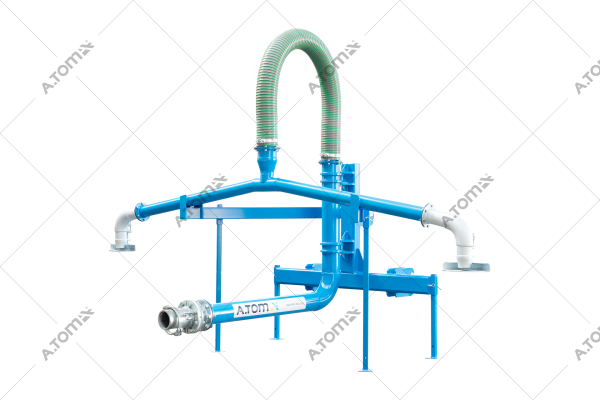

Surface manure applicator A.TOM Twin

This applicator has the same principle of operation. The only difference is that the manure is distributed into two discharge nozzles, which allow covering the surface up to 15 meters. Unlike the deep cultivator method of fertilizing, the applicator does not require the use of a high-power tractor and is much cheaper.

A.TOM specialists are ready to visit your facility in order to select the optimal set of equipment. Only after that, we recommend deciding to buy or rent systems for applying liquid fertilizers to the fields. Contact us for more information!

-cat16.png)