Filter

Filter:

Manure (slurry) lagoon mixer pump: operation and types

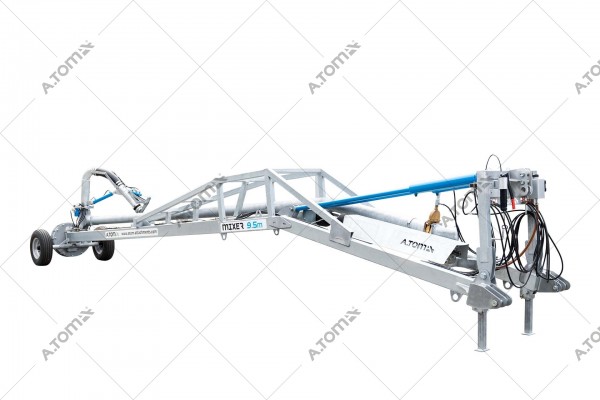

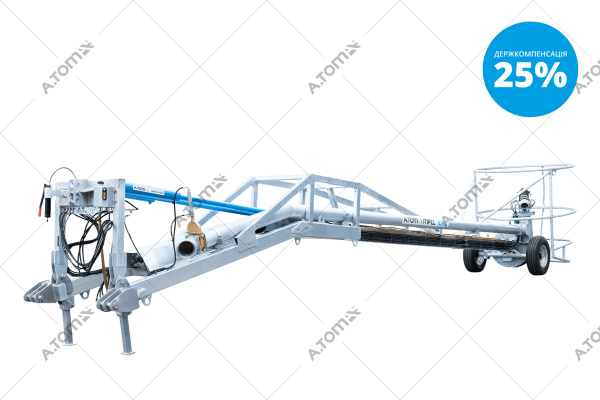

A lagoon mixer pump is specialized equipment designed to mix manure in manure storage facilities to achieve an even, uniform consistency in a short period of time. This is a mandatory procedure before pumping liquid organic fertilizers from the lagoon, allowing to lift solids layers from the bottom or place the crust on the surface of the manure storage facility. Auger-type mixer pumps TM "A.TOM" works much faster than any other impeller-type unit. Mixer pumps are used for mixing and aerating the manure to prevent fermentation and reduce the intensity of unpleasant odors.

Mixer pumps are designed for pumping the manure and filling manure tanks. All models of mixer pumps TM "A.TOM" have a galvanized design, which increases the service life of this equipment during continuous operation in an aggressive environment.

Purpose of mixing the manure

Without mixing the solid fraction either forms a dense crust on the surface or sinks out, which leads to gradual siltation. As a result appears clusters of solid particles, which in the case of film lagoons, are extremely problematic.

The formation of solids on the bottom of the film lagoons leads to a significant decrease in the useful storage volume.

How to choose a lagoon mixer pump?

To choose a lagoon mixer pump, it is necessary to take into account the consistency of the manure mass, which can be either in separated form (solid particles are separated from the liquid fraction) or in non-separated form.

The choice of a lagoon mixer pump depends on such factors:

- Lagoon volume and depth.

- Slope length and lagoon configuration

- Type of manure storage facility (film, iron, soil, concrete; open or closed).

- Percentage of solid manure fraction.

The Ukrainian manufacturer of equipment for the disposal and processing of organic waste "A.TOM" offers a lagoon mixer pump with various modifications:

- Models of different performance, depending on the type and consistency of the material to be mixed. In this case, you should choose a mixer pump with power reserve, for working with high-density manure.

- Models of different lengths for using the equipment in large manure storage facilities with long slopes.

Trailed mixer pumps of different lengths (from 7 to 15 m) can mix up to 20,000 m3 of manure from one point and are aggregated with a tractor with a power of 120 to 200 hp. The mixing speed depends on the power of the mixer, the consistency, and percentage of solids fraction, the clogging of the manure storage facility, and the volume of manure, so it can last half a day or up to 3-4 days. Of course, there are different ways to optimize the working process. Trailed mixer pumps perform the role of both a mixer and a pump, which allows to start the process of pumping and applying manure into the field. Mixer pumps, in addition to mixing manure, are also capable of pumping it out of the storage facility and moving it to other tanks for subsequent transportation. At the same time, the filling speed of a 24c barrel takes only 3 minutes.

Lagoon mixer pumps "A.TOM" have the following features:

- Several lengths are available: 7 m, 9.5 m, 10.5 m, and 15 m.

- Availability of modifications for both closed and open lagoons.

- The volume of mixing from one point is from 10,000 to 15,000 cubic meters.

- Simultaneous or alternate performance of two functions: mixing and pumping

- Nozzle rotation - 300 degrees.

- High-quality imported components of the hydraulic system: Danfoss hydraulic motor (Denmark), Gates hydraulic hoses (Germany), RIV hydraulic valves (Italy).

- ADR axis (Italy).

- Centralized lubrication system.

- Unique mechanical bearing assembly.

- Tractor power consumption - from 120 to 200 hp. depending on the mixer pump model.

- Galvanized design.

For each agricultural complex, our specialists select the optimal equipment, and, if necessary, we can make customized models. Also, we offer services that include a full cycle of works - from mixing the lagoon to the application of organic matter into the fields. Call us or leave a request on the website for detailed information!

-cat16.png)