In stock

Number: 92

Price on application

Since 2019

Basic steel S355

Compatibility:

Description:

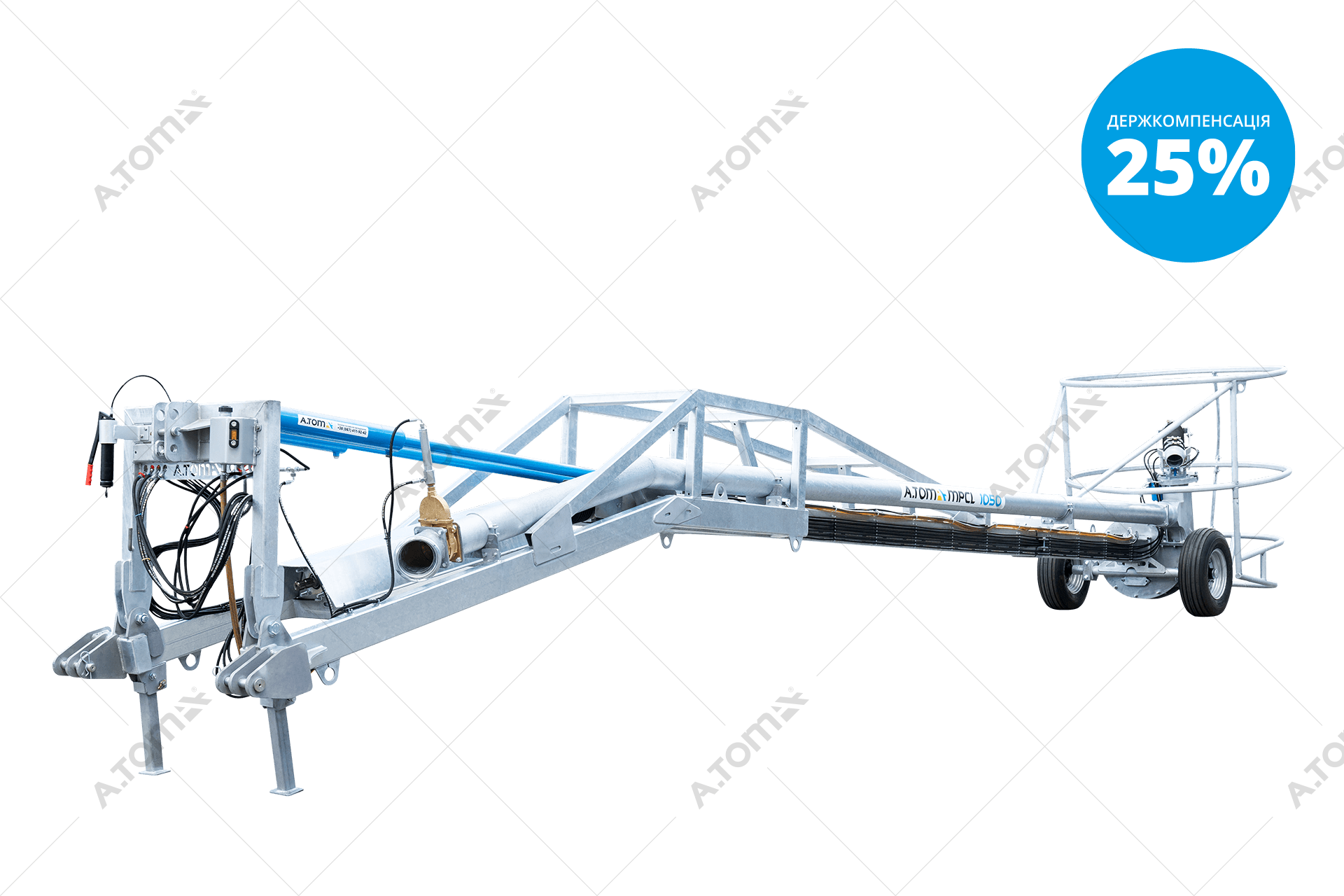

Mixing pump MPCL 950 TM “A.TOM” for mixing closed lagoons, and pumping out liquid manure into the barrels. Length – 9.5 m. The volume of mixing from one point is 20 000 m³, works from the tractor's PTO. Power consumption is 170 hp, 1000 rpm. Weight – 1660 kg. Galvanized construction. Rubber wheels.

Main characteristics Manure (slurry) lagoon mixer pump - А.ТОМ MPCL 950

| Length | 9,5 m |

| Mixing capacity | up to 25 m³/minute |

| Pumping capacity into a tank | 8 m³/minute |

| Mixing volume from one point | up to 20,000 m³ |

| Power | 170 h.p. |

| Weight | 1660 kg |

| Horizontal hydraulic spout rotation | 300° |

| Vertical hydraulic spout rotation | 60° |

| Protective frame | |

| Height | 2,15 m |

| Width | 2,15 m |

More information

1. Robust and durable design

A.TOM MPL 950 lagoon mixer pump is made of high-quality structural steel S355J2. The lagoon mixer pump body and overflow pipe have a galvanized coating both outside and inside.

2. Galvanized coating

The lagoon mixer pump body and overflow pipe have a galvanized coating both outside and inside as it works in an aggressive environment.

3. TVZ / ADR half-axle (Italy)

A.TOM MPL 950 lagoon mixer pump has a pair of wheels that perform two functions. The first function is safe access to the manure storage facility on the slopes without damaging the geomembrane. The second function is moving in short distances between manure storage facilities. The lagoon mixer pump can be transported even in off-road conditions as it has heavy-duty axles from the best European manufacturers.

4. Shortened spraying nozzle

Rotation of the spraying nozzle is designed to break up the layers of solids at different points of the manure storage facility and mix the manure to a uniform consistency. Mixer pumps for closed lagoons have a short spraying nozzle, which can rotate 300 degrees within the radius of the protective frame, as well as move up and down, which allows to lift solids from the lagoon bottom and break it on the surface.

5. Protective metal frame

Mixer pumps for closed lagoons have a protective metal frame, which prevents damage of the film when the mixer is submerged in the lagoon.

6. "Danfoss" hydraulic motor (Denmark)

A.TOM MPL 950 lagoon mixer pump have the hydraulic motor of the world's best manufacturer – "Danfoss" in order to ensure the most efficient performance of the functions as well as for the practical implementation of such benefits as turning, raising, and lowering the spraying nozzle.

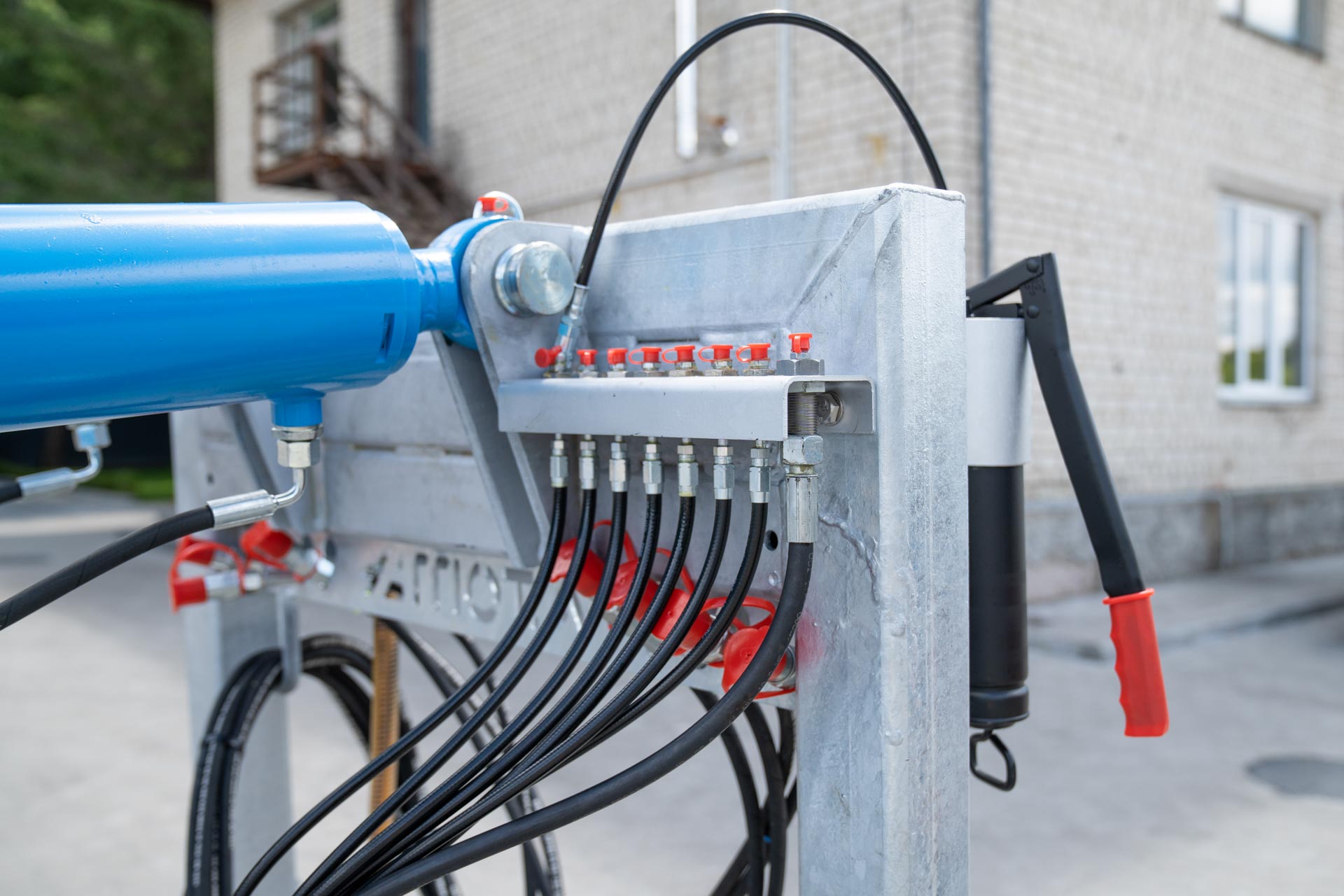

7. «Gates» hydraulic hoses (Germany)

The functions of A.TOM MPL 950 mixer pump depend directly on the quality of the hydraulic system. That is why A.TOM uses reliable and high-quality hoses from a proven German manufacturer of devices and products related to power transmission systems and power hydraulics.

8. "RIV" hydraulic valves (Italy)

One of the most important advantages of lagoon mixers-pumps A.TOM is the ability to pump liquid fertilizers into tanks for manure transportation or pumping into other containers. This function is performed by means of an overflow pipe and hydraulic valves providing the possibility to supply or block the flow of liquid to the overflow pipe or to the spraying nozzle. The use of the European components "RIV" makes this process efficient.

9. Pumping pipe

The upper part of the mixer pump has an overflow pipe, which is used for filling mobile manure tanks. The mixer can perform mixing and pumping functions simultaneously or alternately.

10. Heavy-duty auger

Located inside a special aerodynamic housing at the bottom of the mixer at the end of the lower shaft. It is driven by the tractor's PTO and is used to absorb the fluid and feed it to the spraying nozzle or overflow pipe. When the mixer is in the lagoon, the auger is located parallel to the bottom of the lagoon, which provides better mixing and suction of liquid.

11. Mechanical bearing unit

In the lower part of the mixer housing, there is a mechanical bearing unit - the original development of A.TOM designers. The unit connects to the auger and ensures its uninterrupted operation. The bearings inside this unit are lubricated with transmission oil, which is supplied via a centralized line from the oil tank.

12. “Timken” bearings (USA)

Inside the body of the mixer, there are metal shafts on which installed the ball bearings in spherical housings. All models of mixers have high-quality bearings from one of the best bearing manufacturers in the world - the American company "Timken".

13. Central lubrication system

A convenient system of centralized lubrication with a special gun-type syringe with a flexible hose is provided to facilitate regular maintenance. Lubrication is made by pressing the handle. We use SAE universal lubricant with extreme properties (EP), Nils Nilex EP 2 plastic lubricant (Italy).

14. Parking supports

Galvanized metal parking supports could be folded and unfolded. In the unfolded state is fixed by a pin in a vertical position. They provide lifting of the unit and fixing at a certain height for aggregation with the tractor during commissioning, as well as for fixing in a flat stable position after work.

Similar products

-cat16.png)