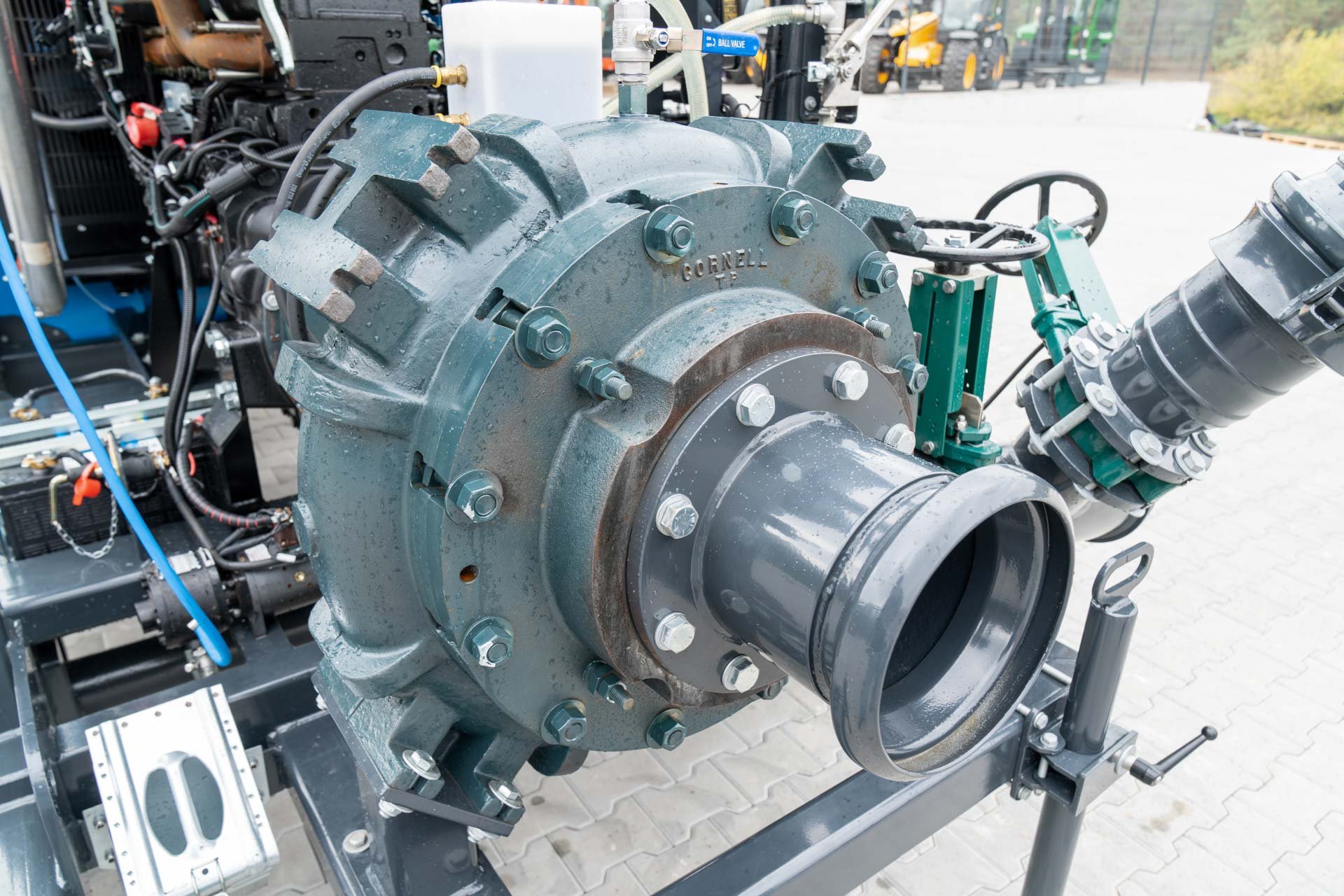

Pump stations A.TOM PUMP 390 equipped with DOOSAN 384 hp engines and Cornell centrifugal pumps, which allow to achieve increased productivity (up to 700 m³/h) with large flows of high pressure liquid. The productivity of such station is 5,000 to 6,000 m³ per day. A.TOM PUMP 390 stations are designed for pumping of liquid manure, liquid effluents from storage facilities and its subsequent application to the fields as organic fertilizers.

Main characteristics Pump station A.TOM PUMP 390

| Capacity | Up to 700 m³/h |

| Length | 5,4 m |

| Height | 2,6 m |

| Width | 2,4 m |

| Weight | 4000 kg |

| Technical specification of Cornell pump 6819MPC-F | |

| Min. flow | 193.1 m3/h |

| Max. flow | 982.3 m3/h |

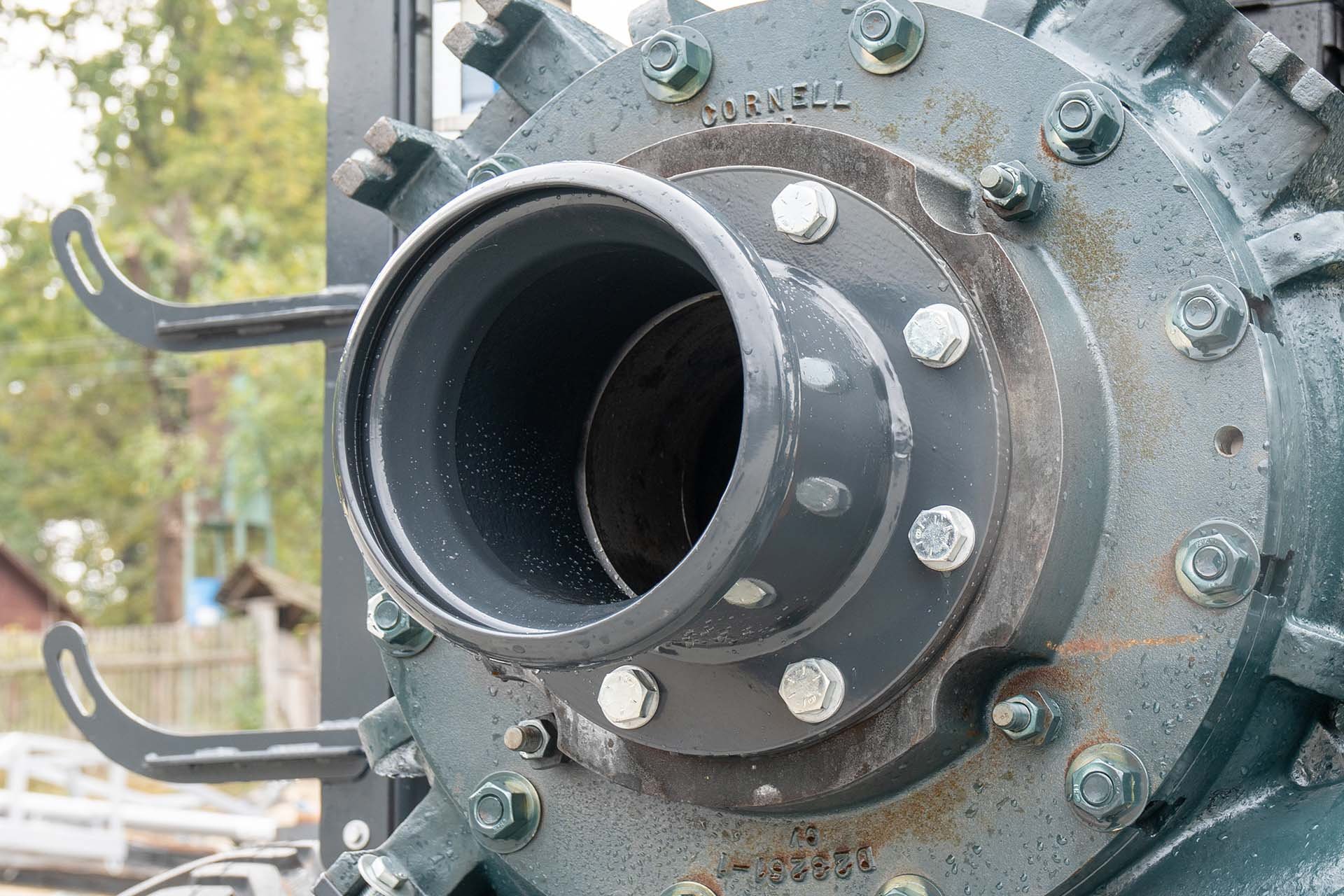

| Discharge size | 152.4 mm |

| Suction pipe size | 203.2 mm |

| Solids handling | 76.2 cm |

| Max. speed | 2000 rpm |

| Shut-off head | 198.4 m |

| BEP head | 158.5 m |

| BEP flow | 709.8 m3/h |

| BEP percent | 77 % |

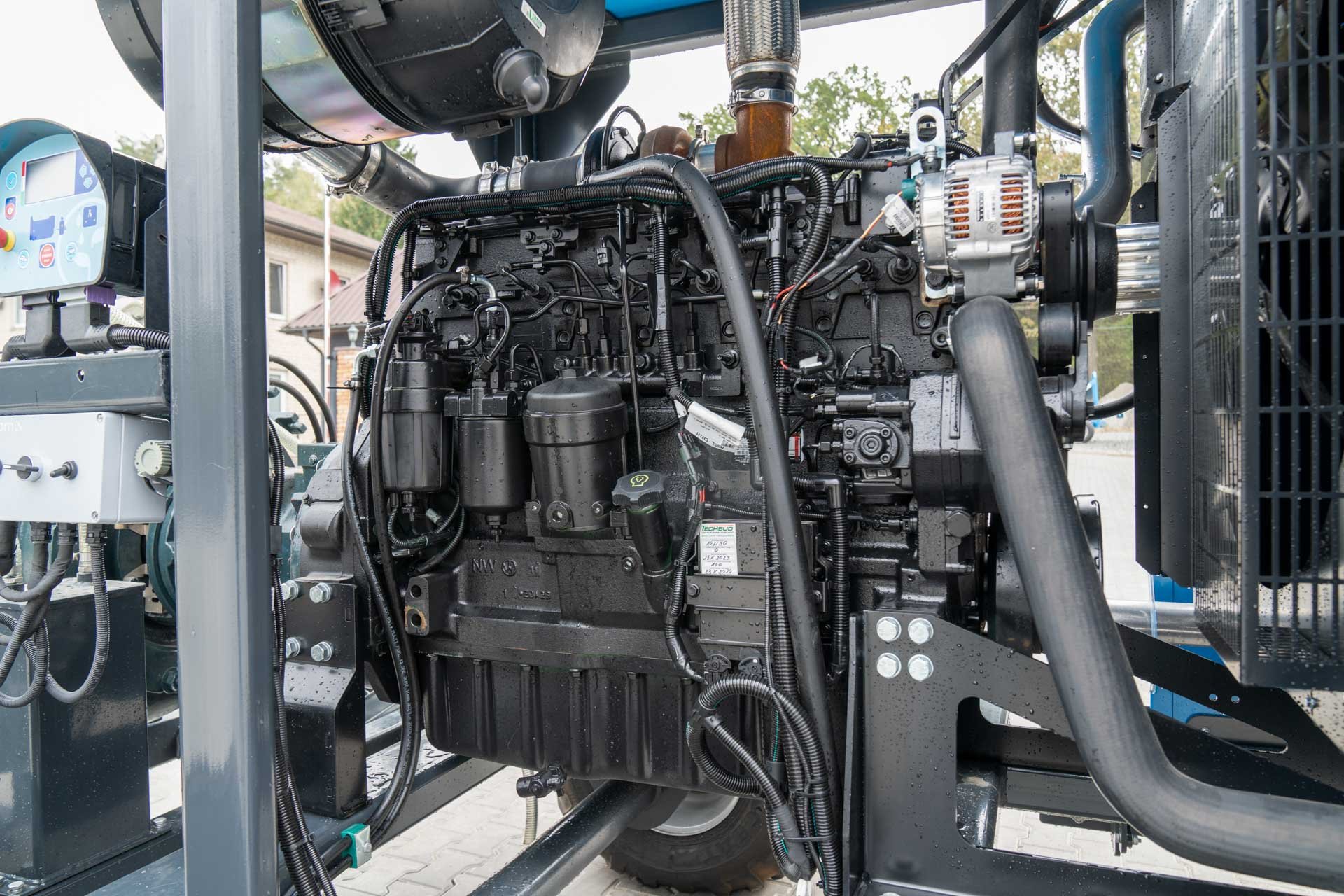

| Technical specification of JOHN DEERE engine | |

| Power | 286 kW / 384 HP / 2200 rpm |

| Max. torque | 1474 Nm |

| Engine type | In-line, 4-Cycle |

| Number of cylinders | 6 pcs. |

| Engine capacity | 9 l |

| Fuel type | Diesel |

| Oil tank capacity | 20 l |

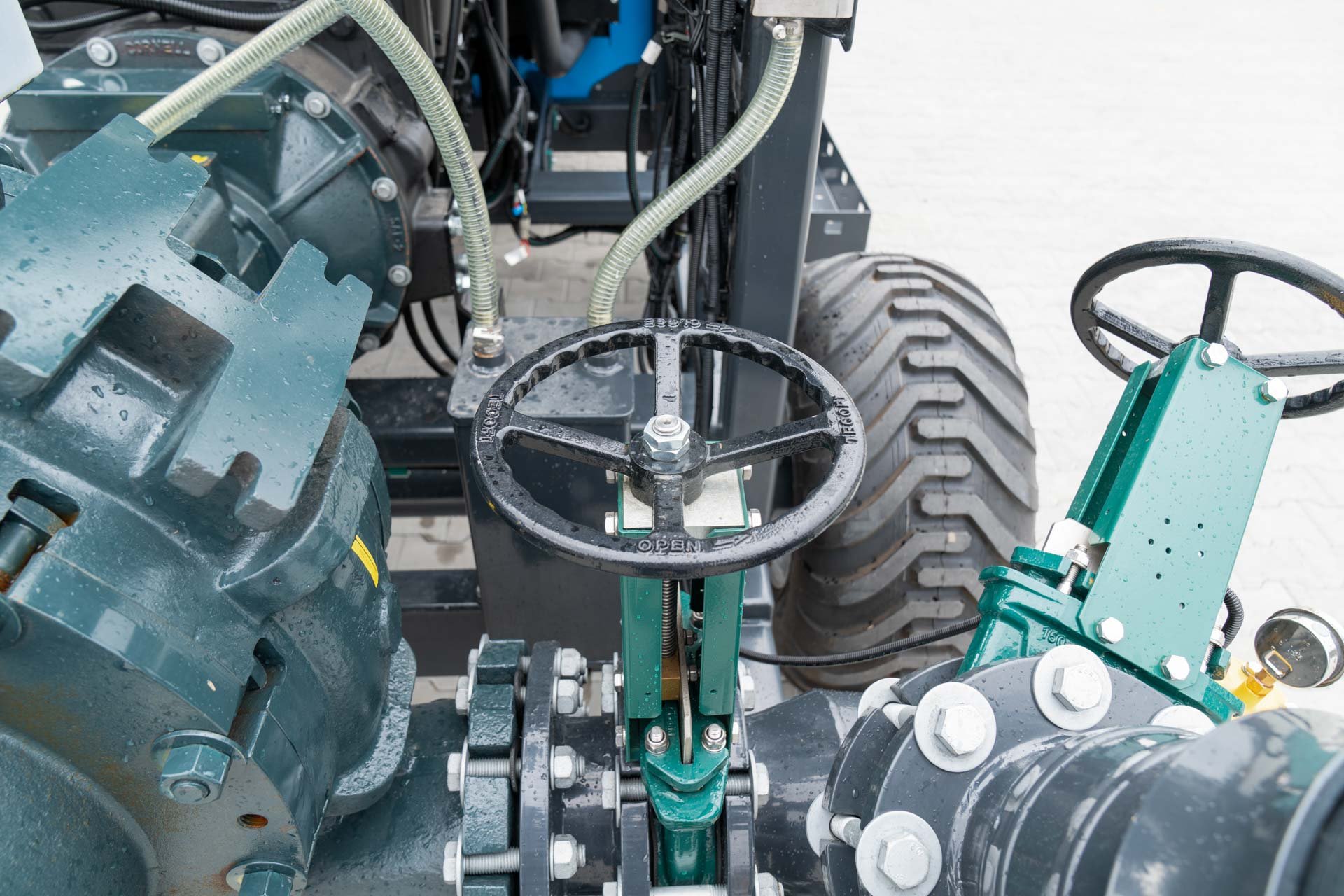

- Cornell Pump 6819MPC-F.

- JOHN DEERE 6090HF475 diesel engine (286 kW; 384 hp at 2200 rpm).

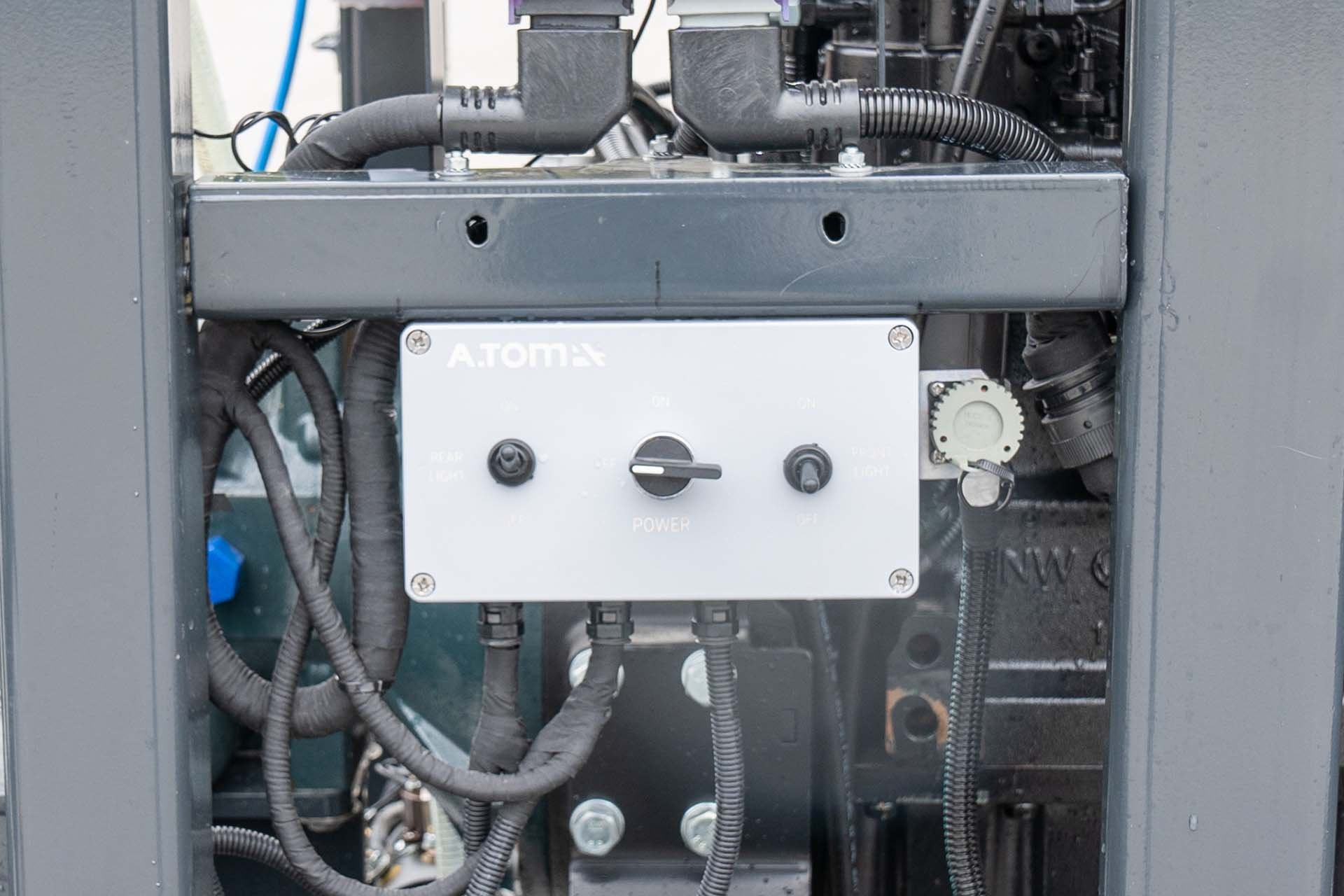

- Control Panel.

- Silencer.

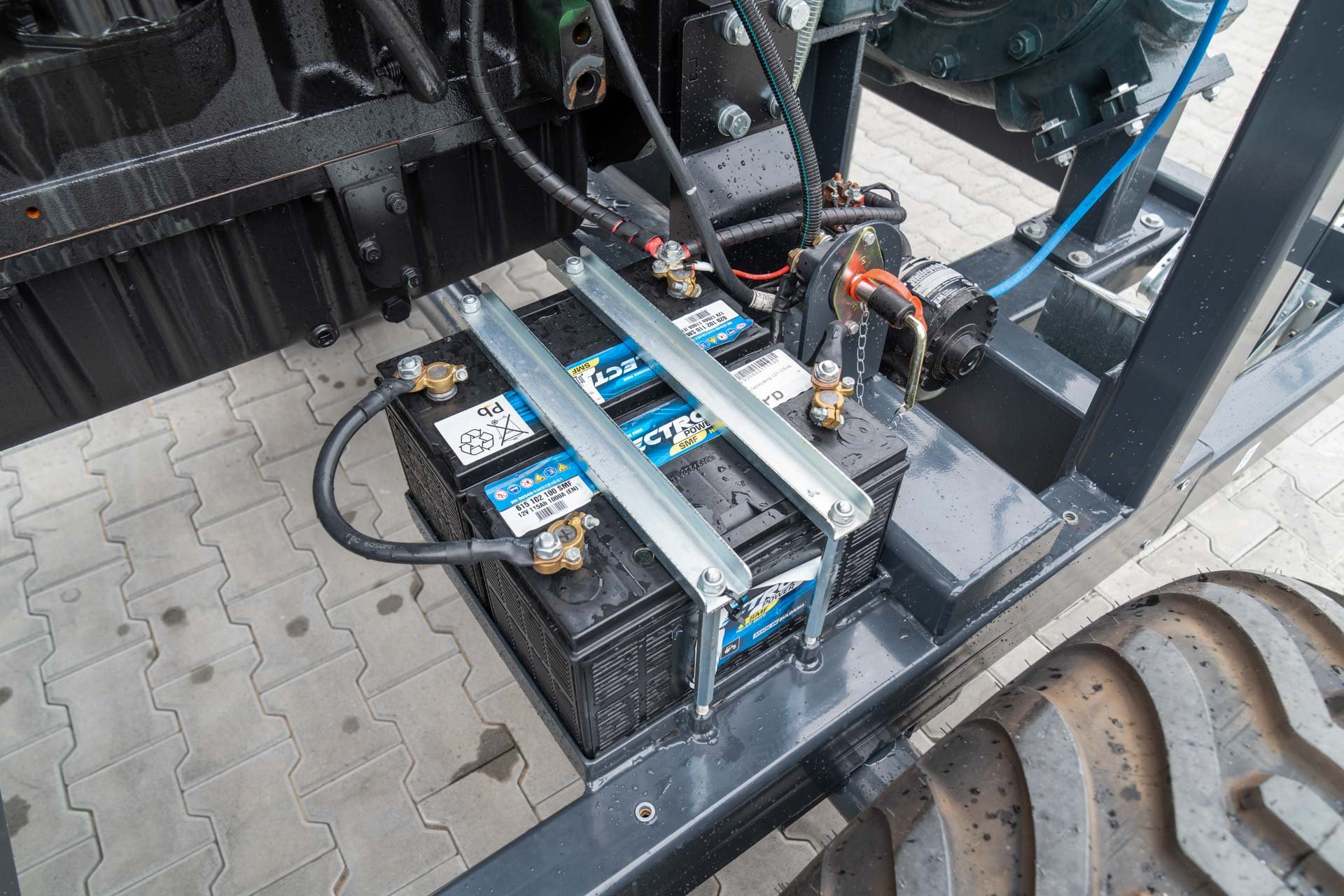

- Battery (12 V) – 2 pc.

- Fuel tank with a standard volume - 560 l.

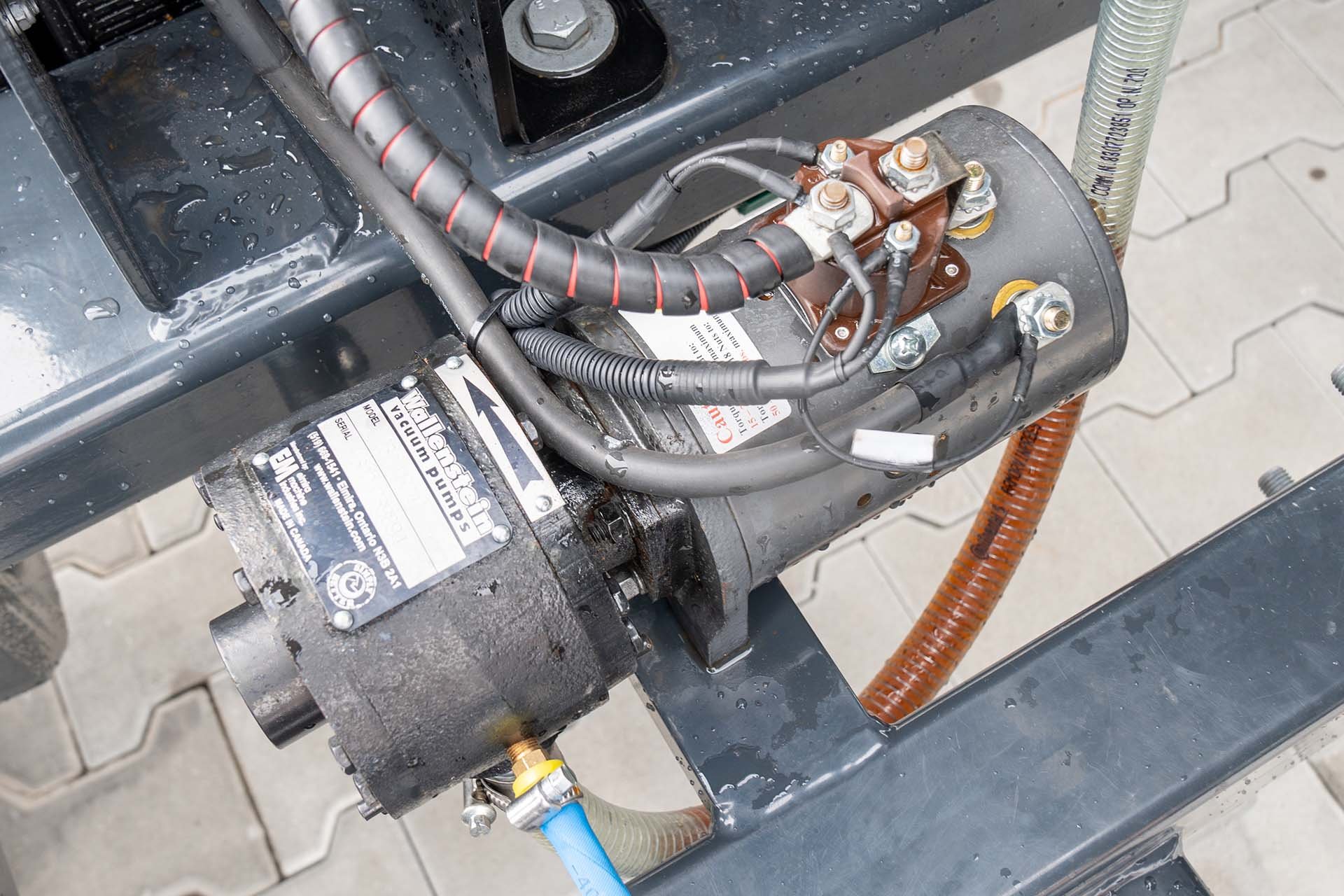

- Generator.

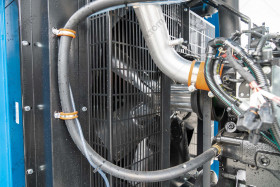

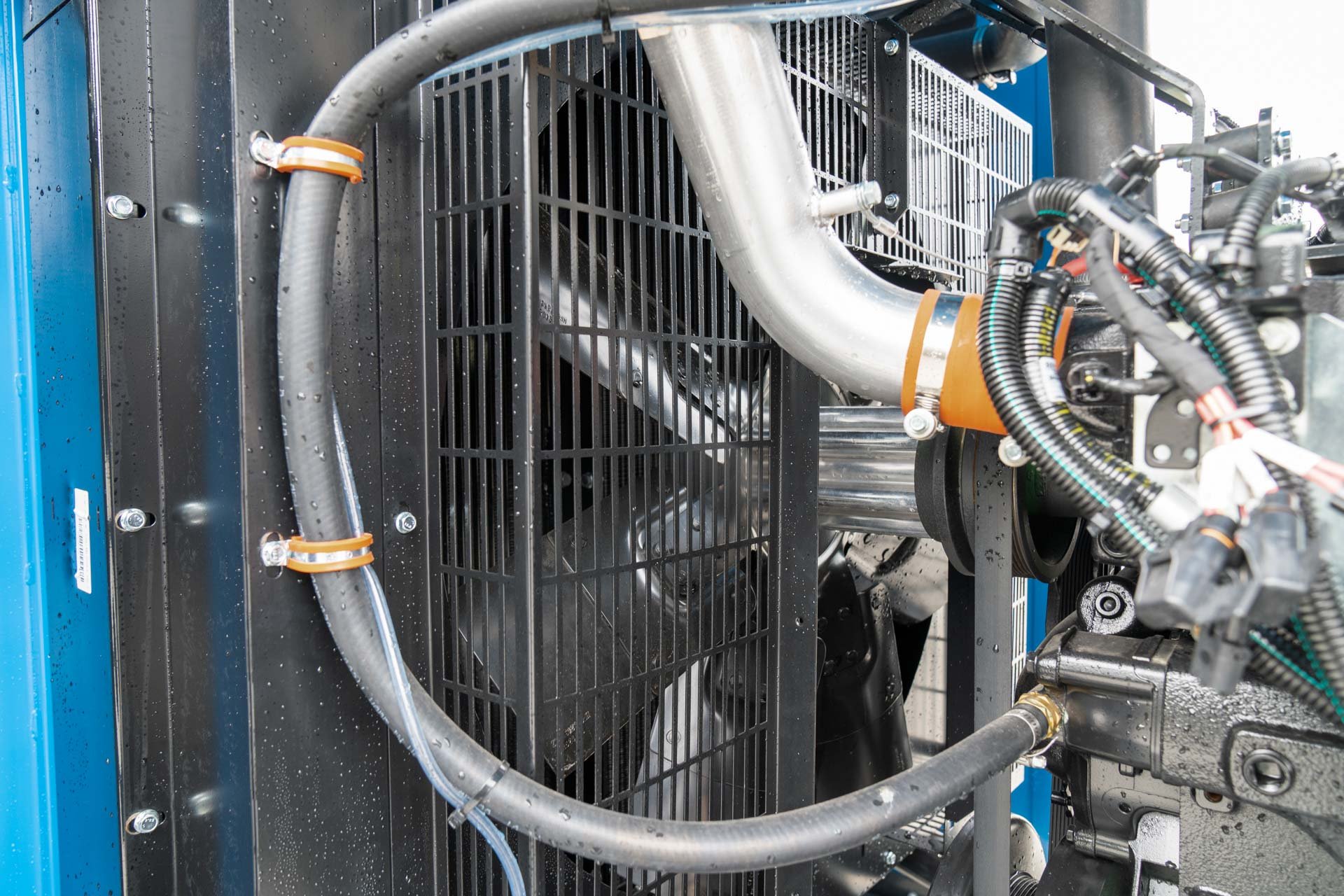

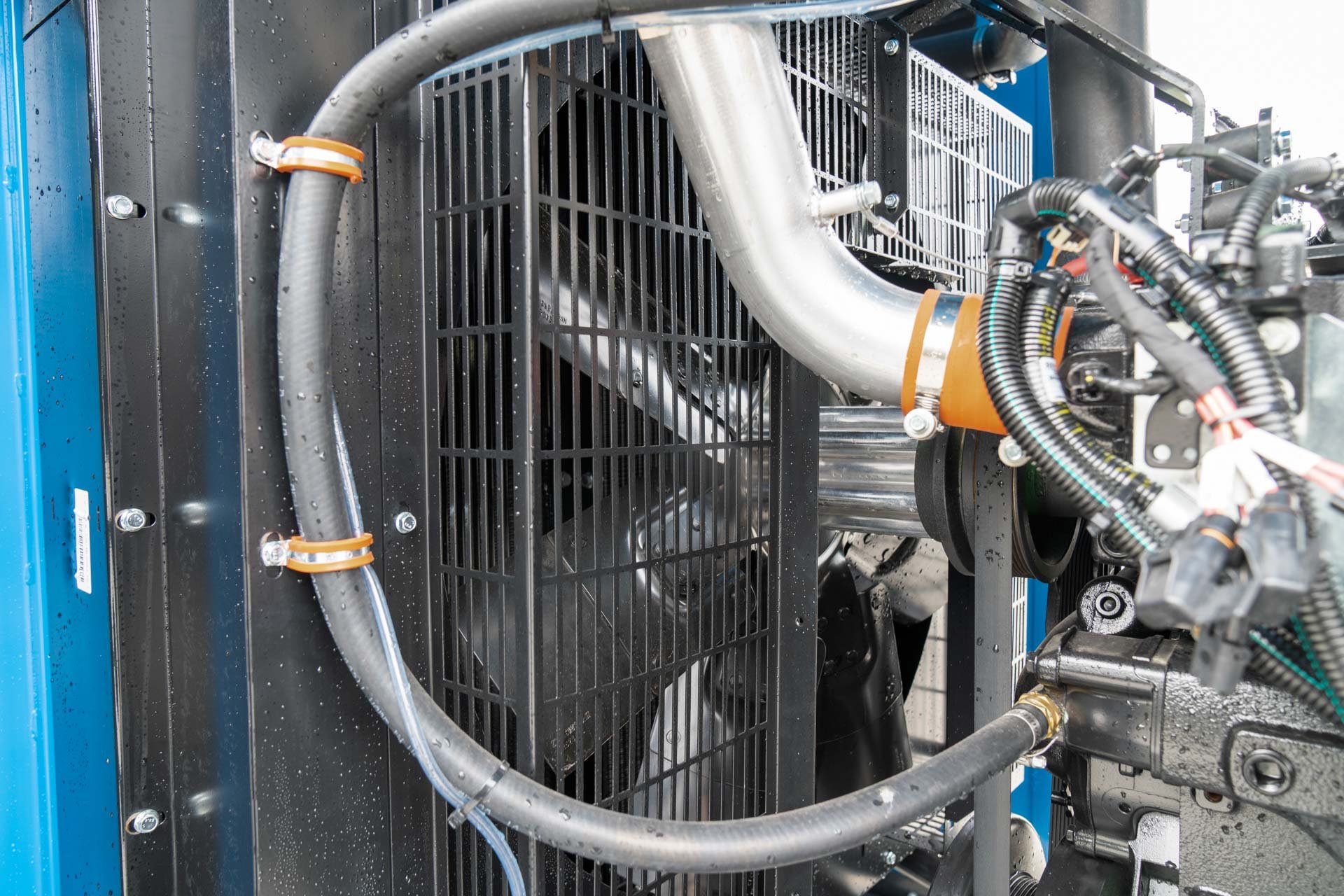

- Extra-large radiator.

- Fan with increased performance.

- Fuel filters.

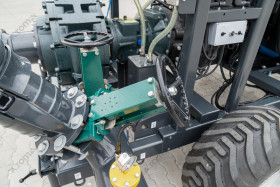

- Single axis chassis.

- Reinforced support frame.

- Reinforced wheel hubs and large-sized wheels, which reduces the consequences of towing in off-road conditions.

- Krohne electromagnetic flow meter.

Systems and sensors:

- ELCOS Control Panel (Italy).

- Operational platform 'ATOM Smart Control Pro'.

- Pressure switch at the pump outlet.

- Emergency oil pressure switch.

- Emergency coolant temperature sensor.

- Analog coolant temperature gauge sensor.

- Pressure gauge with divider at the pump outlet.

Characteristics of Сornell 6819MPC-F centrifugal pump:

- Heavy-duty construction.

- Enclosed impeller for higher efficiency.

- Flow rates up to 982 m³/h / Heads up to 198 m.

- Handles solids up to 76 mm.

- Hardness > 600BHN wears better than standard cast iron.

- RunDry™ option (Indefinite run dry capability).

- Heavy-duty bearing frame.

- Redi-Prime® available for fully-automatic continuous priming.

- Replaceable wear plate.

The body of the pump-diesel station is made of high-quality S355 J2 structural steel and has a powder polymer coating, which is resistant to different factors in an aggressive environment.

Axles of the Italian manufacturer "ADR"/"TVZ" are tested by intensive operation and guarantee stability and ability to move the pump diesel station in off-road conditions. A.TOM PUMP 290 pump-diesel station has transport wheels for moving between manure storage facilities, as well as between farms. For reliability of transportation, the equipment has reinforced hubs and large wheels.

Mounting loops in the station body are designed for safe and easy loading and unloading with the help of cranes.

Metal stabilizing legs could be lowered and raised. In the unfolded state, they are fixed with a lock pin in a vertical position. They provide raising the station and fixing it at a certain height, as well as fixing it in a safe position during the operation.

The reliable and durable Italian-made jack is designed for the convenient and safe operation of the station. Together with the legs, it is used to raise and fix the station at a certain height for connection to the tractor, as well as to fix the equipment after the work is completed.

In the front frame of the station, there is a convenient box for tools and spare parts.

A fuel tank made of galvanized steel with a standard volume of 560 liters from the Turkish manufacturer.

In the upper part of the station, there is a galvanized muffler of Italian production.

On the roof of the station, there are two headlights on telescopic racks for the convenient work at the nighttime.

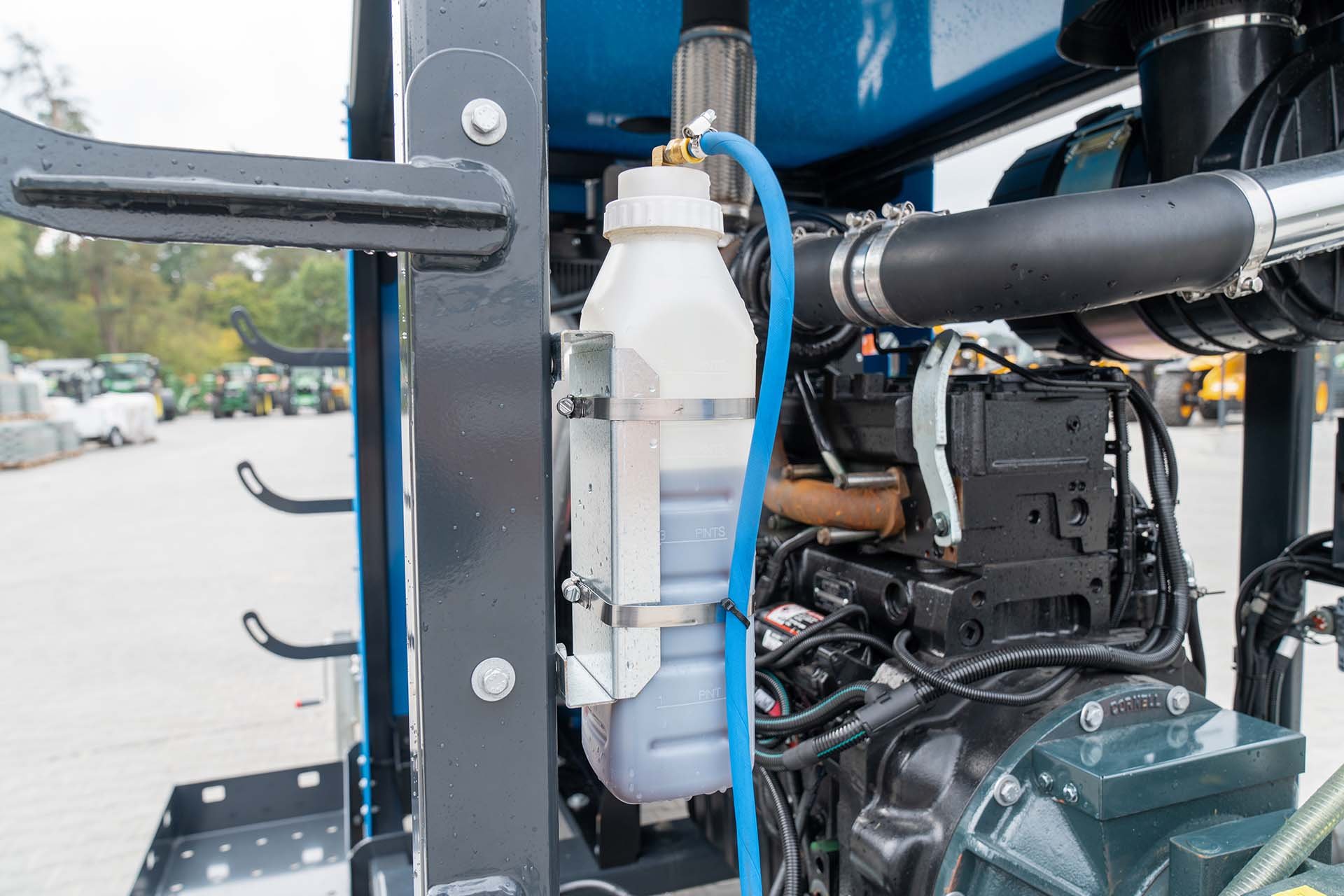

At startup of the station the pump is primed with the oil in the expansion tank, the oil seals are temporarily lubricated until the manure or other pumped liquid reaches the pump.

-cat16.png)