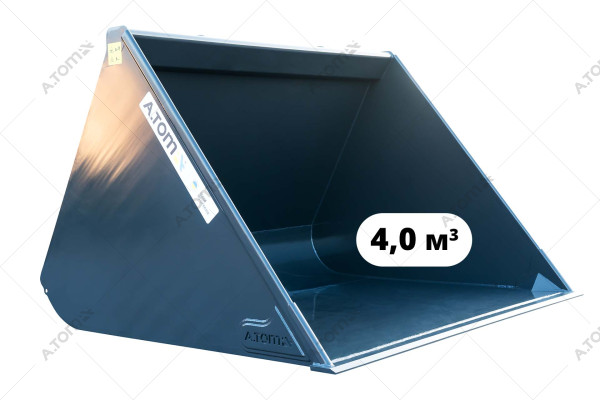

Compost turner - А.ТОМ 3300 (Ukraine). Width — 4707 mm. Height — 1863 mm. Length — 5823 mm.

Main characteristics Compost turner - А.ТОМ 3300

| Max. windrow width | 3.3 m |

| Max. windrow height | 1.8 m |

| Width | 4707 mm |

| Height | 1863 mm |

| Length | 5823 mm |

| Weight | 6750 kg |

| Required power | 120 h.p. |

| Сapacity | 1200 m³/h |

| Operation speed | 0.3-0.4 km/h |

The trapezoidal frame of the compost turner is made of high-quality structural steel S355 J2 and powder polymer coating.

Rather prompt and easy shifting the equipment from working into transport position is one of the advantages of A.TOM compost turners. Compost turner has transport wheels for moving between manure storage facilities, as well as between farms located at a certain distance. The possibility of movement in off-road conditions is ensured by the use of high-quality and durable axles from one of the best Italian manufacturers - ADR or TVZ.

A trailer with a counterweight is designed for efficient and safe movement of the equipment.

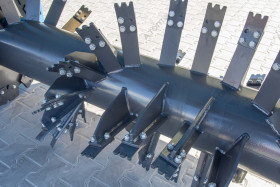

Compost turner is designed to process any type of raw material: both materials of plant origin and animal wastes. High-quality mixing of the material is achieved due to a heavy-duty drum and a special configuration of blades

A set of wear-resistant blades is made of Hardox heavy-duty steel as the drum with blades designated for work in the aggressive environment

The deflector that is located in the rear part of the frame performs two functions: it forms a windrow of a trapezoidal shape and protects against stones or pieces of compostable raw materials

Special rubber deflectors are located in the front and the back of the frame and protects against stones or pieces of compostable raw material

Heavy-duty gearbox from "Bondioli&Pavesi" - an Italian developer and manufacturer of components and power transmission mechanisms for industrial and agricultural machines. Provides high productivity and efficient mixing of raw materials (up to 40,000 m3 per year).

In order to provide trouble-free operation of the compost turner in severe environment and designated for work being installed at certain precise angles we use cardan shafts of earlier mentioned above well-known Italian brand “Bondioli&Pavesi”.

Special ball bearings in spherical housings are used in the design of the turner’s drum. All models of compost turners are equipped with high-quality bearings from one of the best manufacturers in the world - the American company “Timken”.

A heavy-duty hydraulic cylinder with a strong pin is used to lift up and put down the turner’s trapezoidal frame.

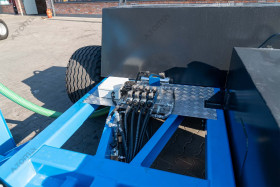

The functions of the compost turner directly depend on the reliable and efficient operation of the hydraulic system. That's why we have chosen reliable hydraulic hoses from Europe's leading manufacturer of power transmission and power hydraulic appliances and systems

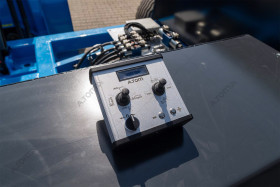

For efficient and ergonomic operation of the compost turner hydraulic system from the tractor cab during operation, a remote control is provided.

The compost turner is easily and quickly aggregated with the tractor by means of hydraulic height adjustment of the drawbar location with a coupling device

The tractor hydraulics drive the hydraulic motor located on the wheel, which makes it possible to ensure forced movement and rotation of the wheel, preventing wheel slippage in the wet field. On the bracket attached to the wheel there is a hydraulic cylinder, which can be used to adjust the height of the tedder drum in a windrow

Reliable and durable European-made jacks for the convenient and safe operation of the compost turner. It provides lifting and holding the equipment at a certain height for attaching to the tractor, as well as for fixing it in a stable position after work is completed.

Mounting loops are designed for the convenient loading and unloading of the compost turner.

-cat16.png)