Option: Differentiated application of organic fertilizers – A.TOM ‘Smart Organic Fertilisers Spreading’ software

To increase the efficiency of organic fertiliser applications such as cattle manure, chicken manure, compost, defecate and others, there is a growing trend towards the use of differential spreading systems. This system provides for the distribution of organic fertilisers on cardinally different parts of the field, according to the data of the established field map, which is developed on the basis of various types of information: soil type, soil analysis, pH level, nutrient content, yield maps, relief, soil conductivity map, etc., taking into account the planned crop rotations.

Maximising the use of the right amount of organic fertiliser in the right place to realise the potential of each heterogeneous field area and available resources to improve soil health and achieve additional economic benefits. Among other benefits, facts such as:

- observance of a positive balance of nutrient elements;

- control of the quantity and quality of fertiliser applied;

- improvement of biological, chemical and physical soil conditions;

- significant reduction of mineral fertiliser costs;

- fertiliser savings of up to 40%;

- optimisation of input resource use;

- increased crop yields.

To implement the system of differential application of organic fertilisers, our specialists have developed the unique A.TOM software ‘Smart Organic Fertilisers Spreading’, which has been successfully integrated into the A.TOM 24 organic fertiliser spreader. This software ensures optimal application of organic fertilisers.

MAIN FUNCTIONS

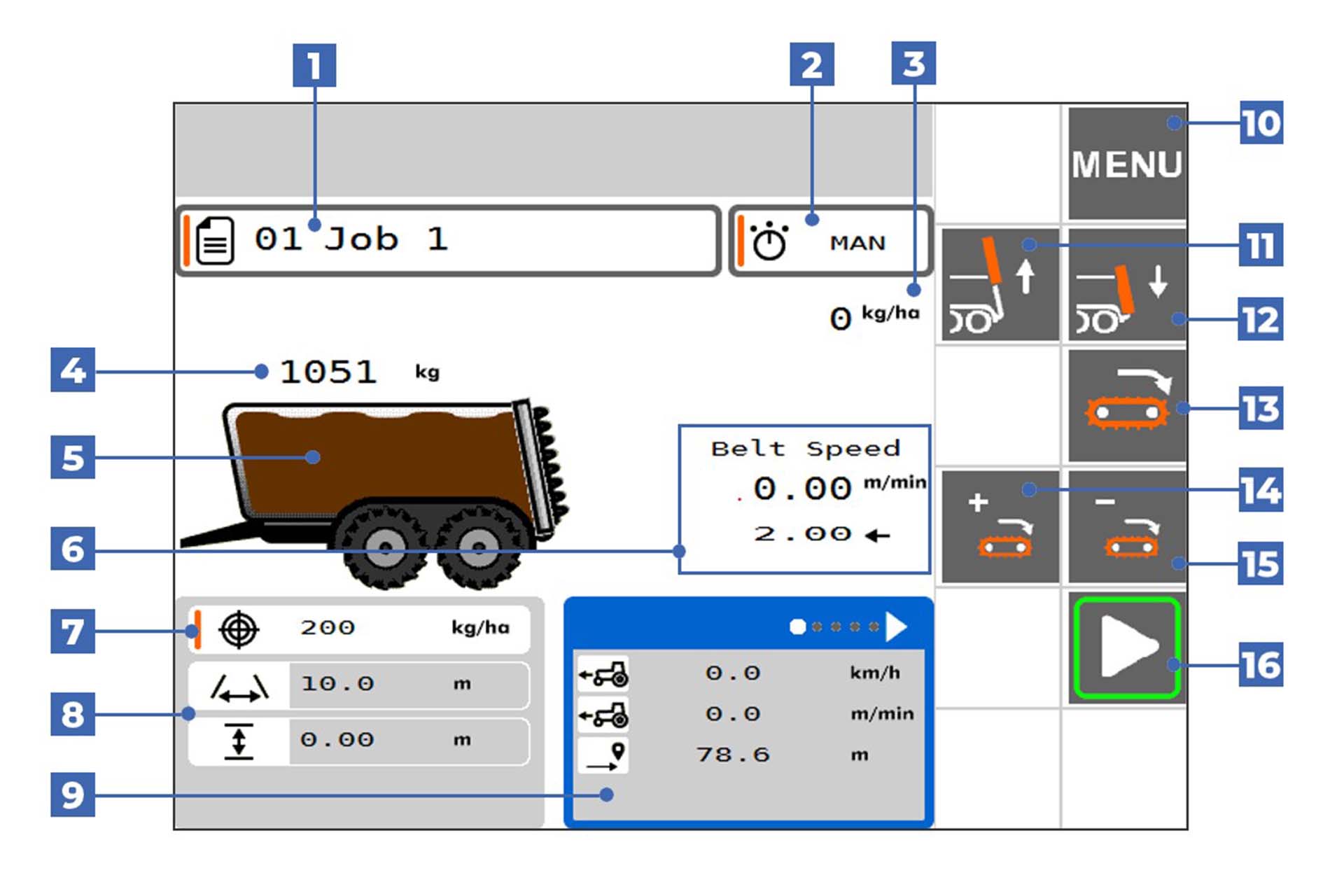

- AUTOMATIC ADJUSTMENT OF THE APPLICATION RATE.

- CONTROL OF THE CONVEYOR SPEED.

- CONTROL OF THE REAR OPENING/CLOSING GATE.

- DETERMINATION OF THE SPEED OF THE BEATERS.

- ISOBUS.

- DYNAMIC WEIGHING.

- DISPLAY OF VARIOUS PARAMETERS ON THE DISPLAY.

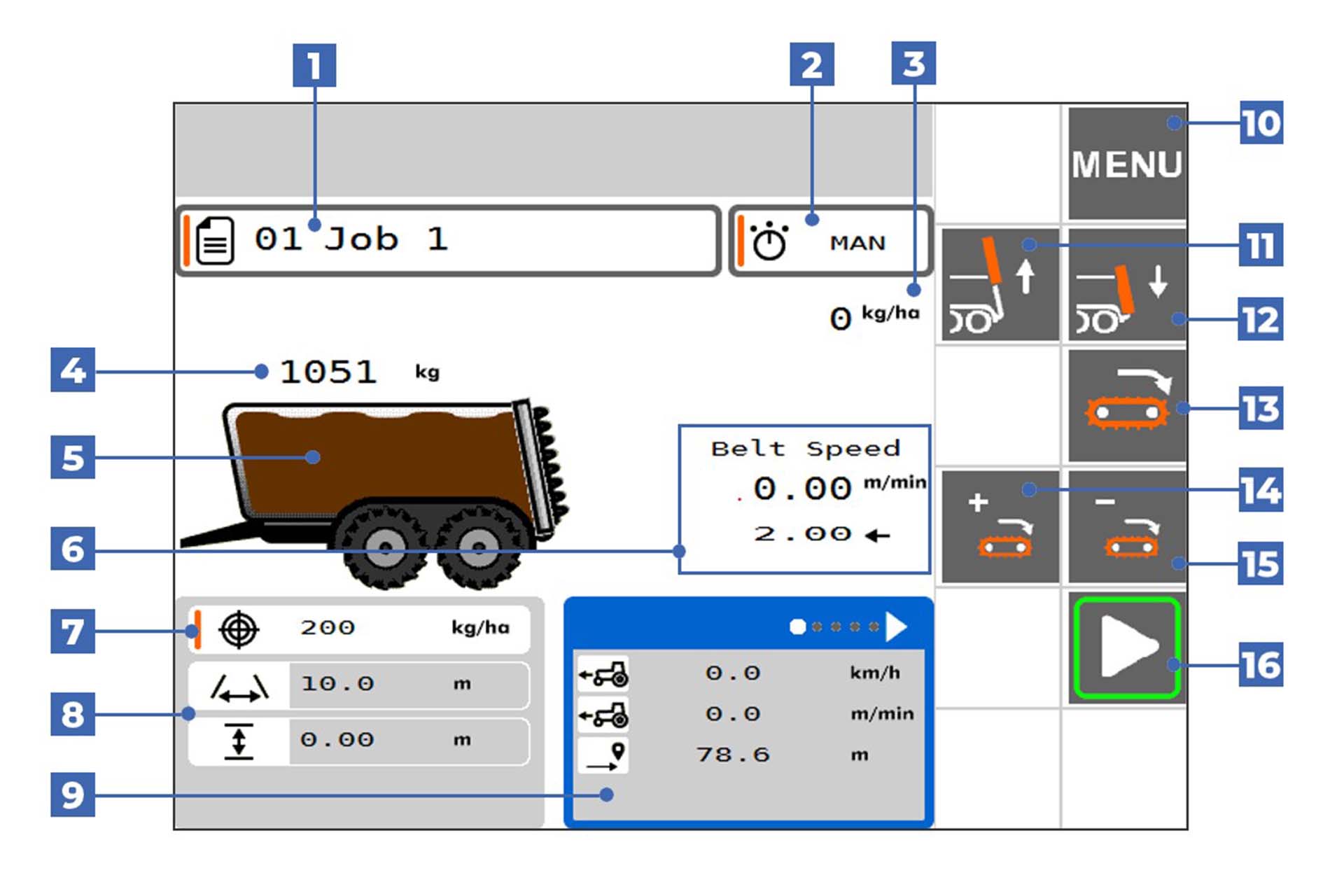

The job computer adjusts the application rate to the set target rate and can be controlled by hydraulic actuators. Simple menu navigation provides easy access to the functions, while the work screen provides the operator with all the important information.

In the tractor cab, a user-friendly menu is displayed on the display, which shows all the relevant parameters:

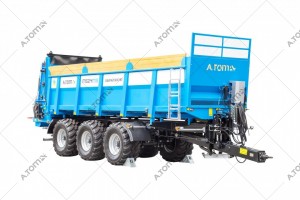

1. Heavy-duty spreader body design

Heavy-duty spreader body designed for transporting large volumes of organic fertilizers. The body is made of high-quality structural steel S355 J2. Body volume - 24 m3.

2. Powder coating

The spreader works in an aggressive environment and has a powder polymer coating

3. Double-row bottom conveyor

The bottom of the body has a two-row scraper conveyor, which has two pairs of heavy-duty chains connected by welded U-profile metal bars. Powered by a hydraulic drive.

4. Heavy-duty chains

Four heavy-duty (breaking load - 25 t / chain) chains with round links lay into inside space of special designed stars to avoid wear. All chains are drawn in a synchronic way. Conveyor bars that feed the material move along a separate wear-resistant guide.

5. Automatic chain tensioning system

Located in front of the body. Could be seen from the tractor cab, which allows adjusting all the chains of the bottom conveyor, ensuring reliability and running smoothness.

6. Electro-hydraulic speed control of the conveyor

An important feature of the manure spreader is the electro-hydraulic control of the conveyor, which provides convenient adjustment of its speed directly from the tractor with the help of an ergonomic control panel. The main advantage of electro-hydraulic control is its smooth adjustment during spreading. At the end of the cycle, when the amount of manure has decreased, it is necessary to reduce the speed of the tractor or speed up the movement of the conveyor to control the dosing.

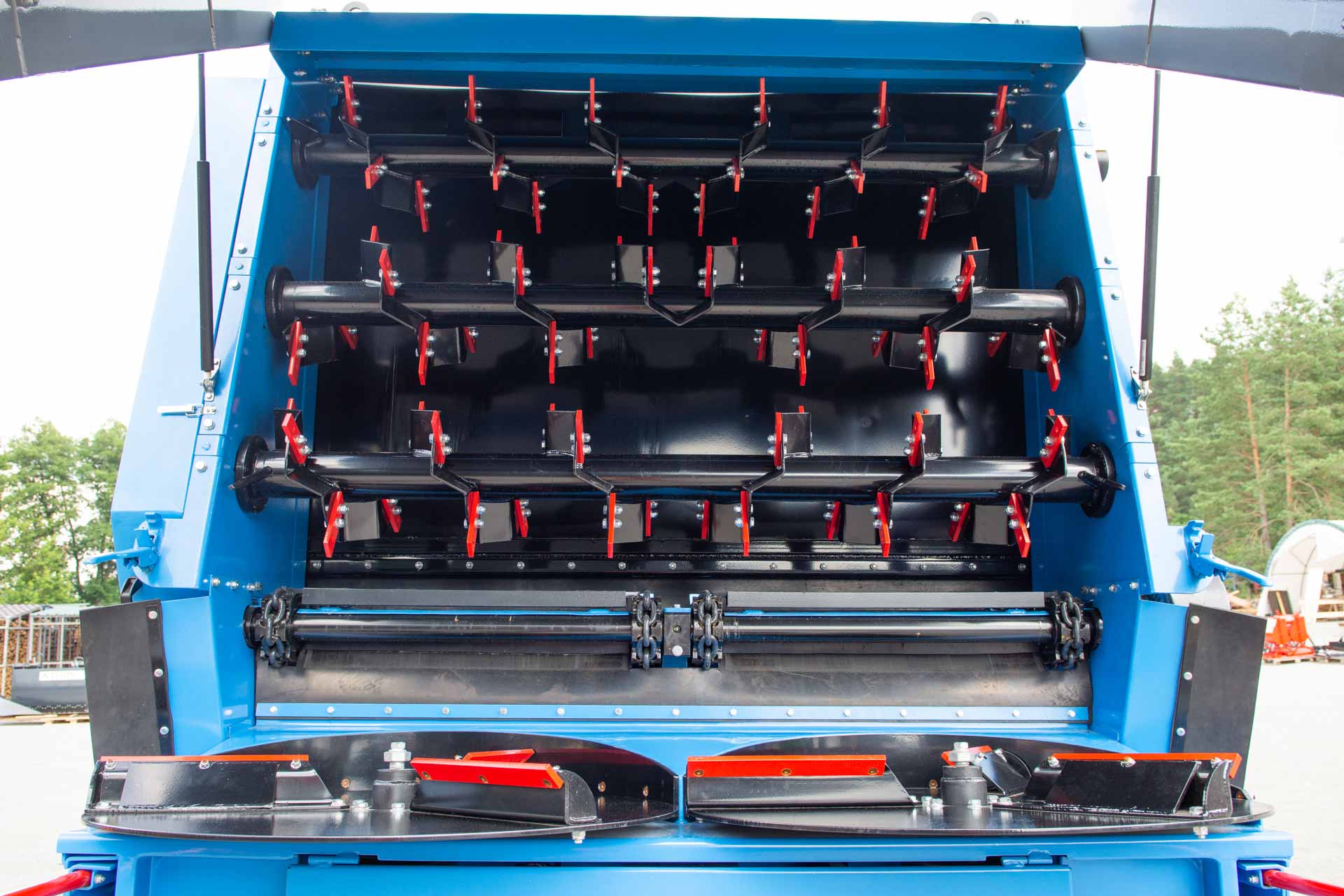

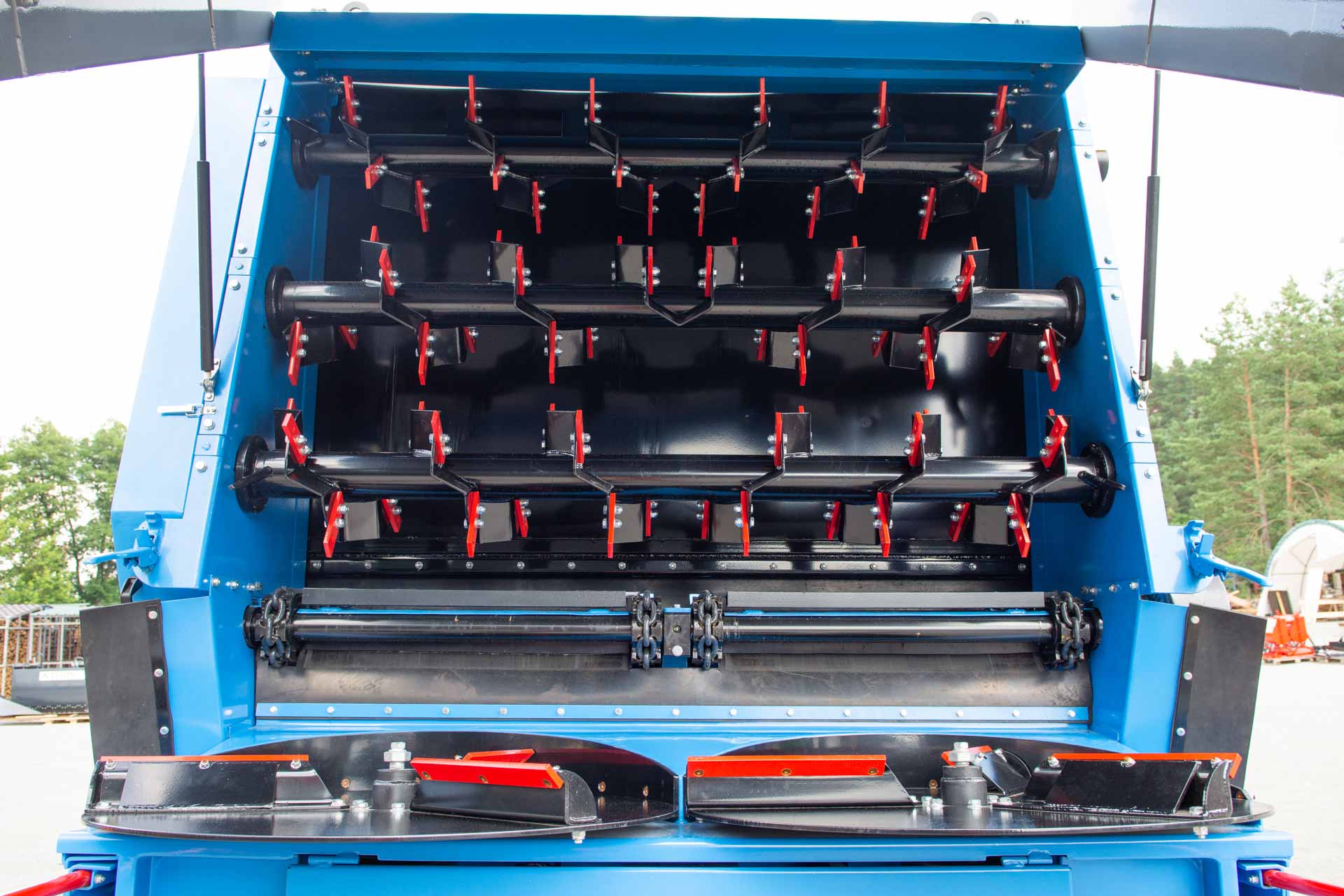

7. Shredding mechanism

Used for shredding and feeding the material to the spreader. It consists of three horizontal crushing beaters and knives. The shredder works with the help of a chain drive, which is actuated from the tractor’s PTO. Crushing beaters, knives, and discs are made of high-strength wear-resistant steel Hardox (Sweden).

8. Spreading mechanism

Consists of two spreading discs, with three or six blades attached to the discs with bolts and nuts. Shear bolts protect the blades. The spreading device provides the width of application up to 24 m. Efficient width of spreading - 16 m

9. Three-axle chassis

Universal three-axle chassis is designed to transport a variety of organic materials weighing up to 30 tons. The front and rear axles rotates, that improves maneuverability and facilitates movement in the field. Also in reverse mode, the rear axle is locked.

10. Interchangeable bodies

A special system of interchangeable bodies provides the use of different bodies on one universal chassis. For example, instead of a spreader body, you can install a trailer body for grain, silage, a platform for transporting bales, and even a tank for transportation of liquid fertilizers. This system allows using one chassis to perform many operations, ensuring efficient operation throughout the year.

11. Wide wheels

The low own weight and the use of wide wheels (BKT 560/60 R22.5) reduce the load on the ground and prevent excessive compaction.

12. Brake system

The basic configuration includes a double-circuit hydraulic brake system, which, depending on the customer's needs, can be replaced by a pneumatic one.

13. ADR / TVZ axis (Italy)

Durable springs and axles are designed for safe and smooth movement in the field, from the manure storage to the field and vice versa. Stability and ability to move in off-road conditions are ensured using high-quality strong axles and springs from one of the best European manufacturers "TVZ" or "ADR" (Italy).

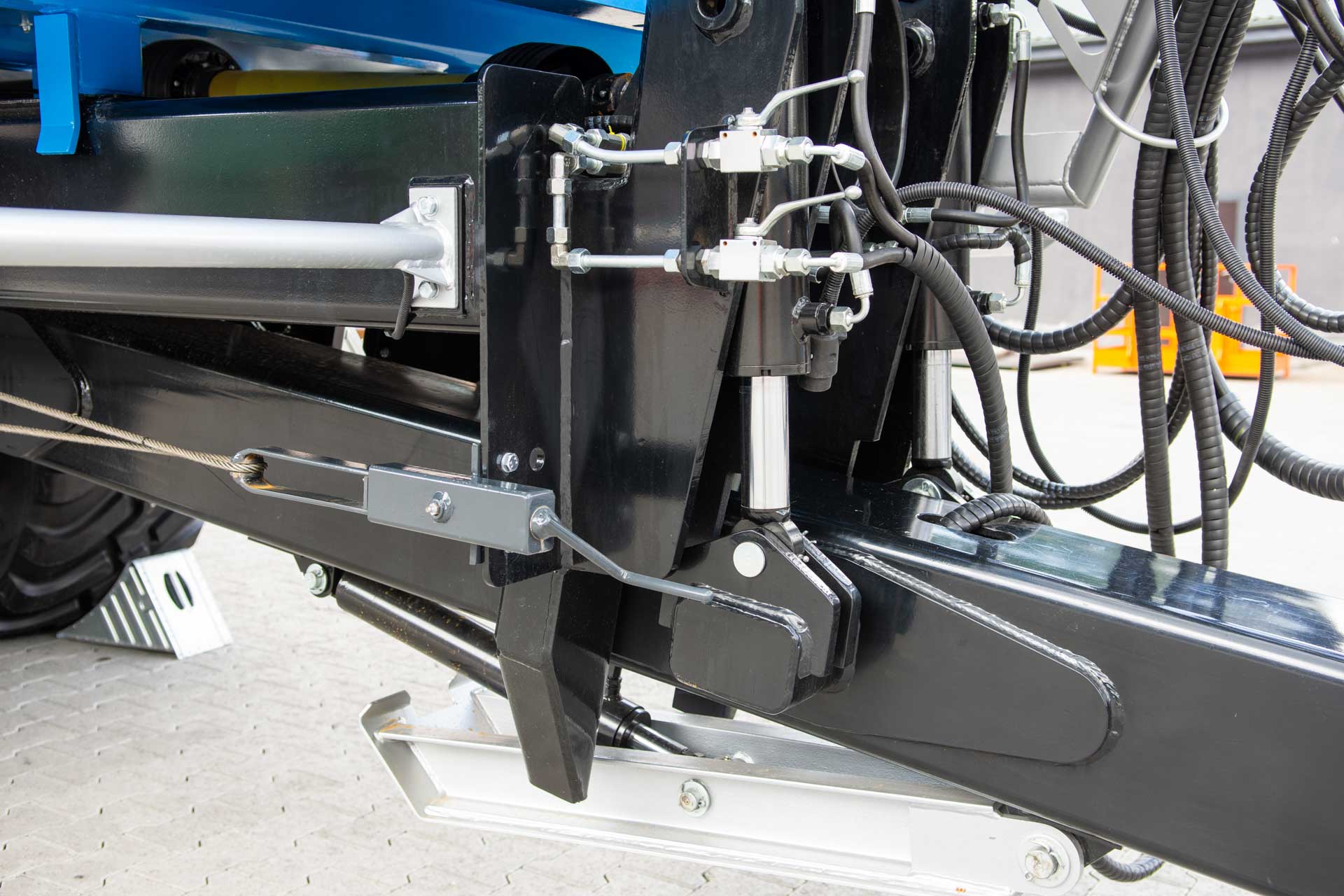

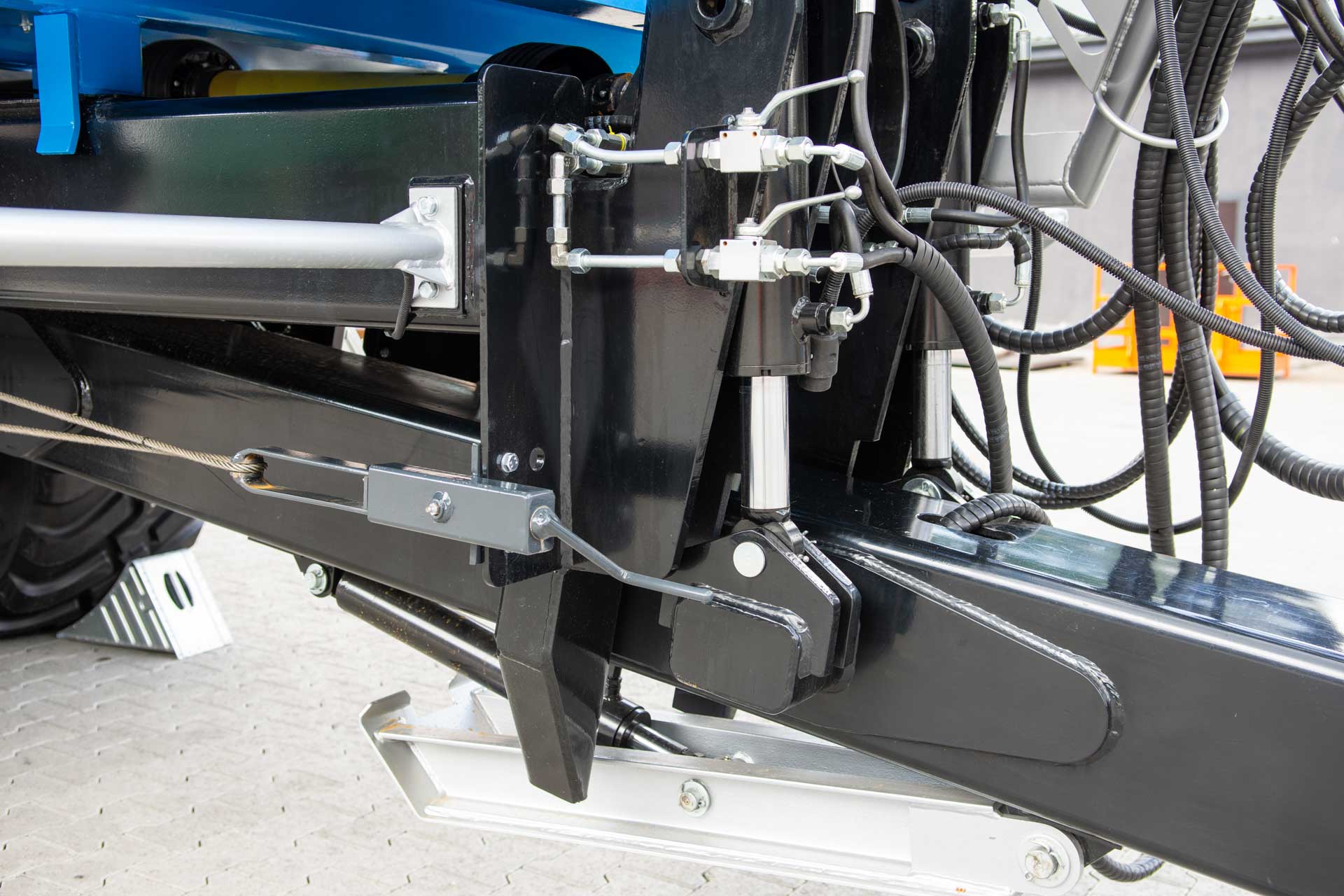

14. Hydraulically adjustable parking supports

For reliable fixing of spreader position.

15. Hydraulic suspension of the drawbar

Two hydraulic cylinders for lowering and raising the drawbar are designed for convenience and facilitation of aggregation with a tractor and uncoupling after work.

16. Hydraulic adjustment of the rear guillotine

Hydraulically adjustable rear guillotine in the semi-open position allows to control the width of the spreading, and in the closed position - prevents the spillage of organic material during its transportation to the field.

17. Hydraulic hoses "Gates" (Germany)

Reliable and high-quality hoses of a proven European manufacturer are used to ensure the efficient operation of the A.TOM MS 24 spreader hydraulic system.

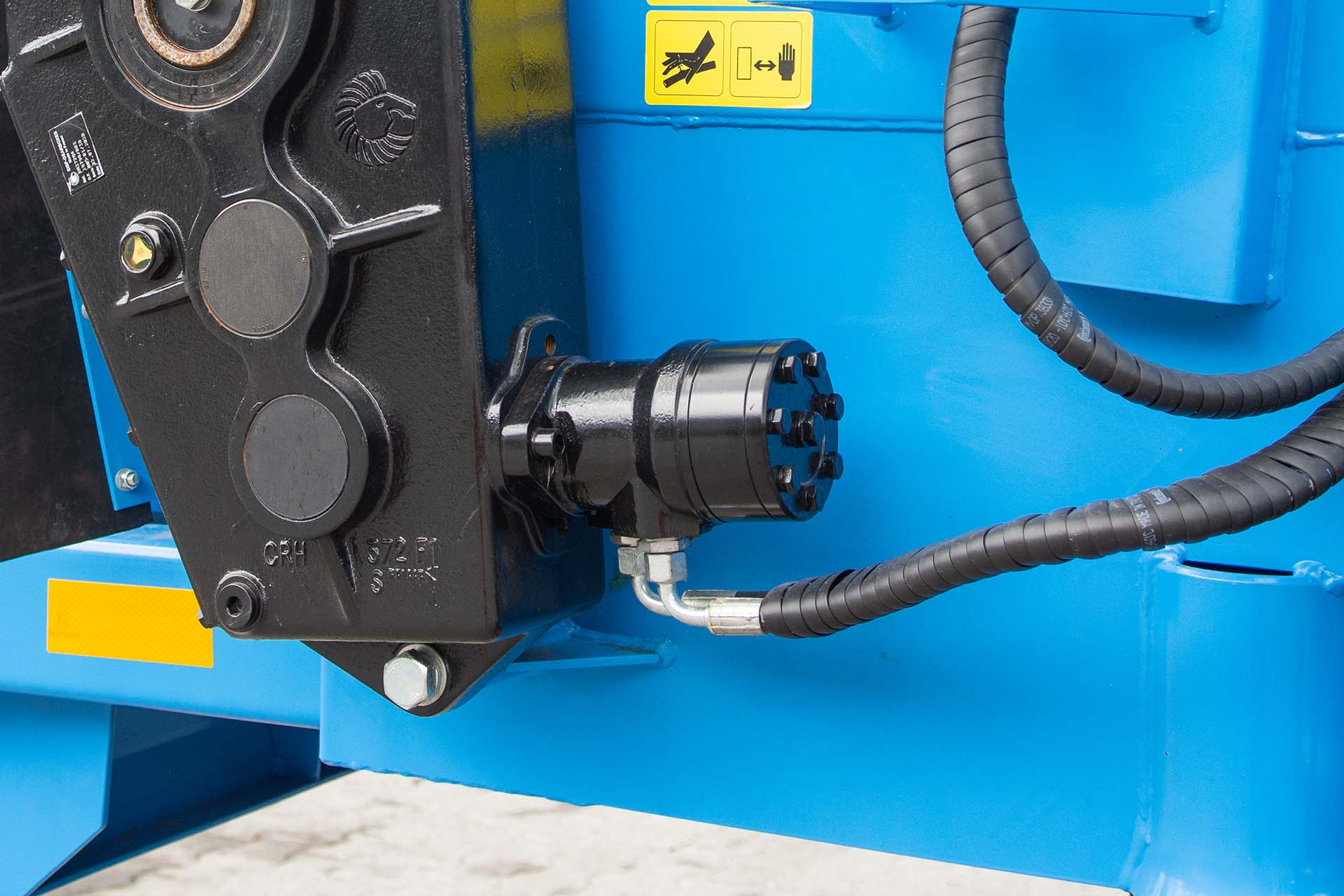

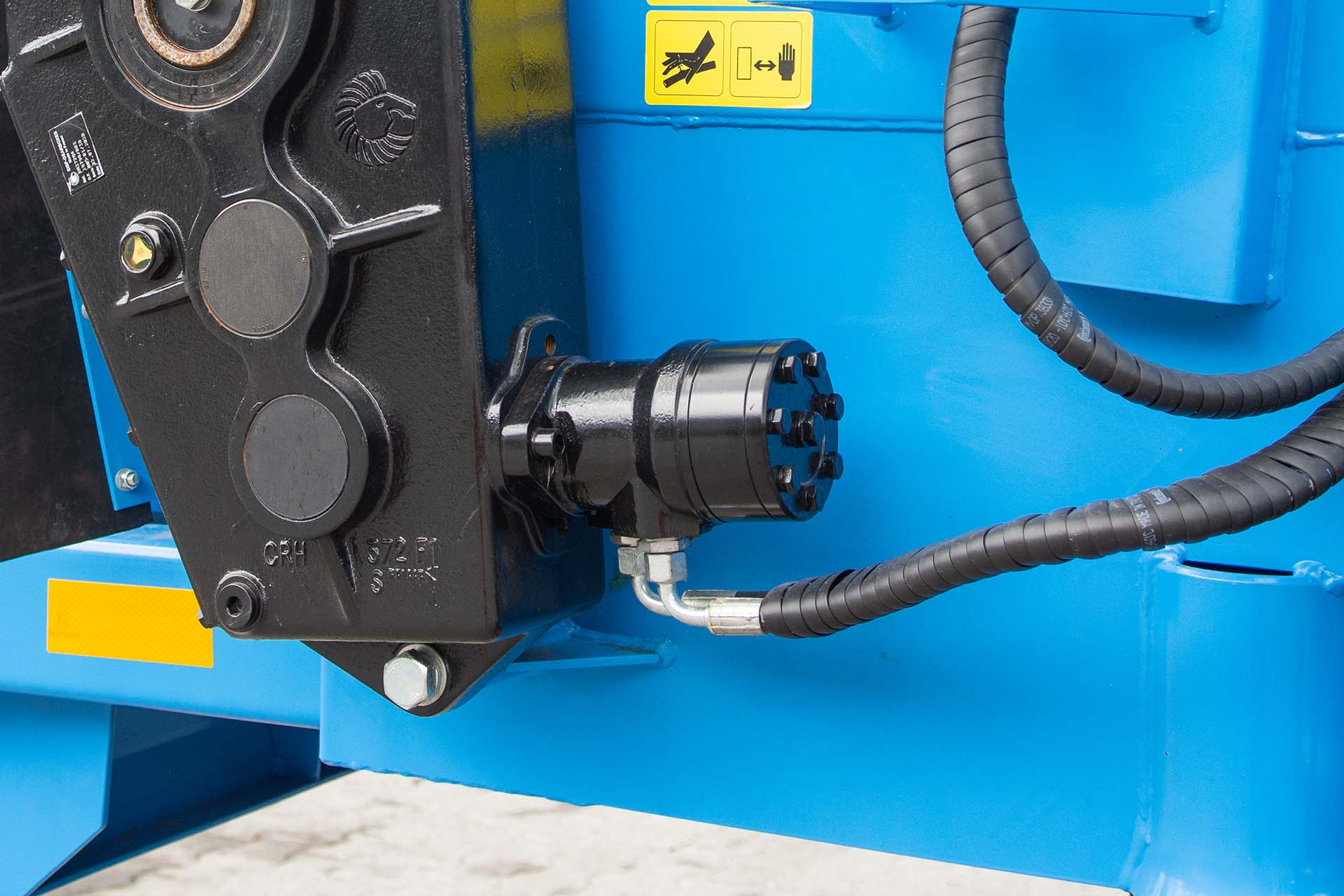

18. "Danfoss" hydraulic motors (Denmark)

The spreading drive works with the help of cardan, which is driven by PTO. The scraper conveyor is driven by a hydraulic motor. This eliminates the need for high-power tractors. We use devices from the best manufacturer of hydraulic motors in the world "Danfoss".

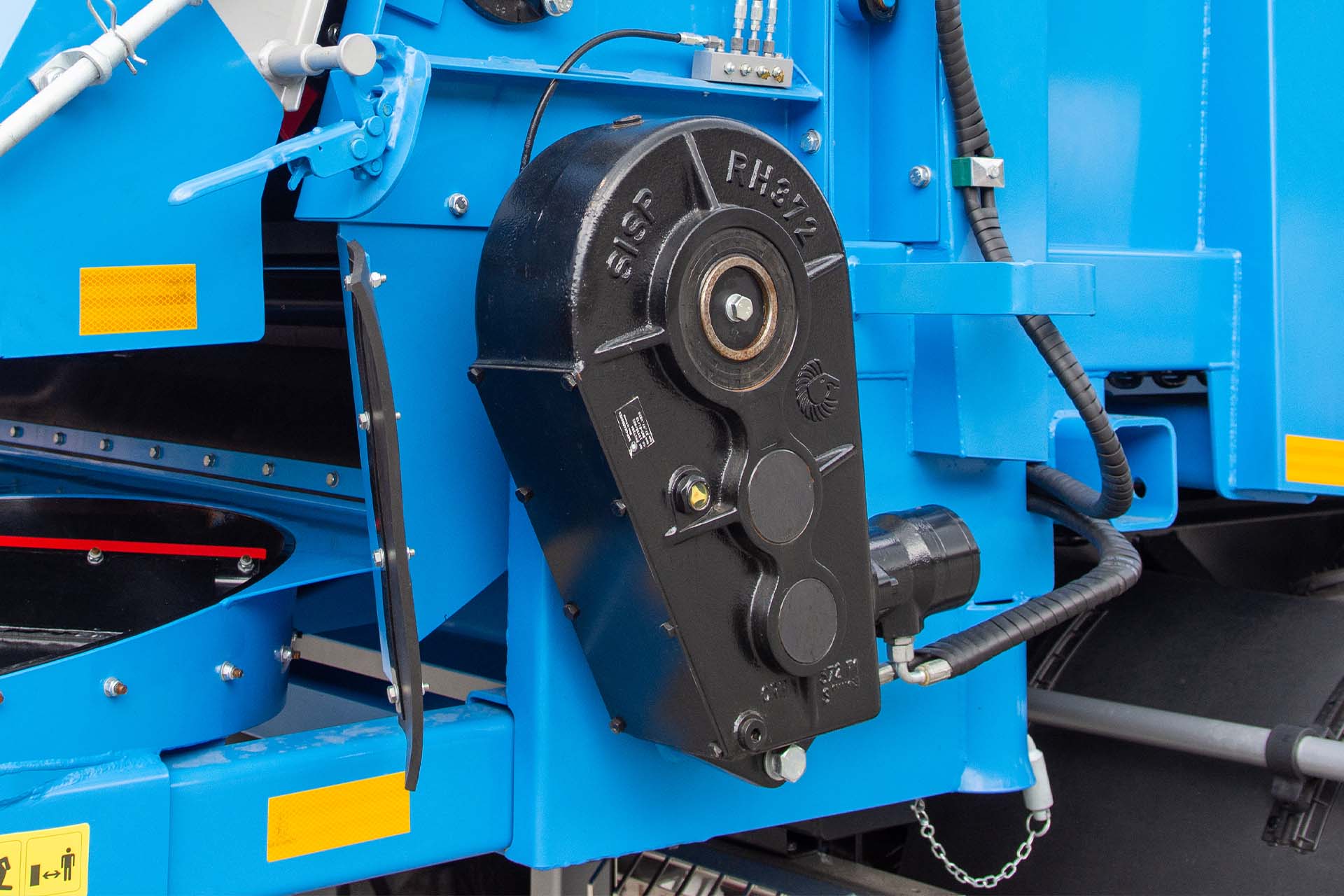

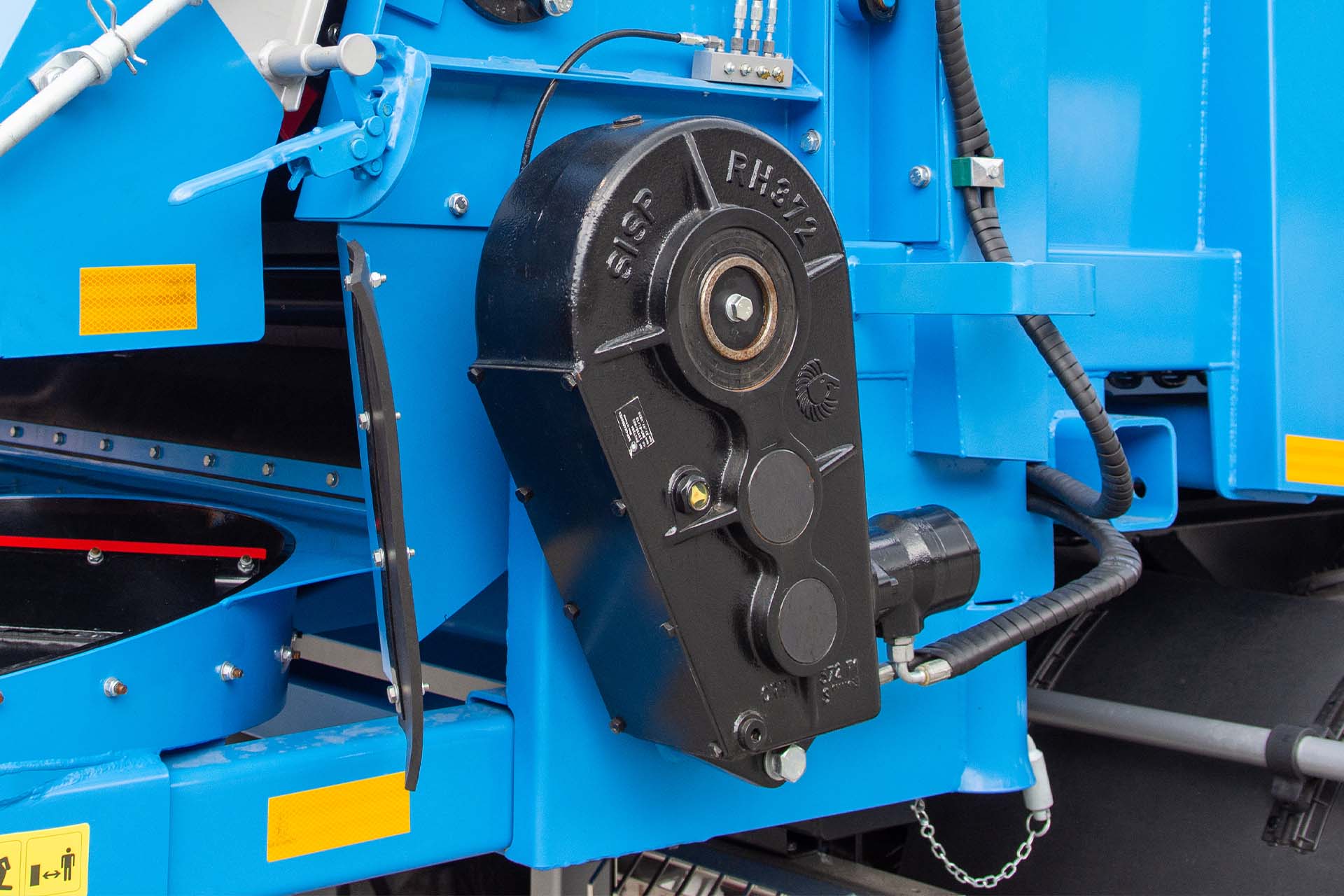

19. Powerful SISP reducers (France)

All gearboxes and shafts are designed to work under heavy loads. The choice of powerful gearboxes of European production was made taking into account the realities of domestic farms.

20. Coupling device

The coupling device is a removable hook - a loop with a 50 mm diameter made by "Schwarzmuller" (Germany).

21. Lighting and optics

Devices of the leading manufacturer of the industry - the Polish brand "Horpol".

22. "Wings" - mudguards "Domar" (Italy)

For reliable protection, including dirt, and to ensure the smooth movement of the wheels.

-cat16.png)